Introduction to the DJ-W Series High-Concentration Ozone Water Generator for Agricultural Applications

Release date:

2023-03-09

The scientific and technological project applying DJ-type electrolytic ozone generators to crop cultivation is primarily funded by Jinhua Guangyuan Instrument Factory. Established in 2007, the company specializes in the R&D, manufacturing, and sales of a series of products, including electrolytic ozone generation modules and electrolytic ozone generators. The company boasts domestically advanced ozone production facilities and testing equipment, and has introduced from Germany internationally advanced production processes and management technologies. By actively attracting and cultivating technical talent and leveraging the support of research institutes, the company has adopted a path of introduction, digestion, and re-innovation. In 2007, the company participated in the national Ministry of Science and Technology’s foreign cooperation project titled “Research on the Development, Integration, and Application of Novel Pesticide Substitution Technologies.” Through this technical collaboration, the company successfully developed the DJ-W series of high-concentration ozone water machines, which have been fully applied throughout the entire process of replacing chemical pesticides for controlling plant diseases and achieving the expected results.

-

Technical Introduction to the DJ-W Series Ozone Water Generator

The DJ-W series ozone water generator is a proprietary patented technology developed by Guangyuan Instrument Factory. This technology uses pure water as its raw material and produces ozone via low-pressure electrolysis, requiring no auxiliary materials or additives whatsoever. The resulting ozone concentration can reach as high as 18-20% (by weight of the released gas), which is 6 to 20 times higher than that produced by conventional high-pressure air-based ozone generators. The ozone gas produced is accompanied solely by oxygen, with absolutely no secondary pollution. Thanks to its built-in cooling and moisture-resistant features, there’s no need to install additional equipment such as cooling or dehumidification systems. Furthermore, this machine is equipped with a built-in, highly efficient gas-liquid mixing technology. By integrating advanced manufacturing methods from Japan and Taiwan, our factory has maximized both mixing efficiency and ozone concentration. Compared with similar products available domestically and internationally, this machine boasts superior ozone mixing efficiency, a compact size, and significant cost savings as well as reduced energy consumption.

Product application scope:

This product is widely used in industries such as pharmaceuticals, healthcare, food processing, drinking water treatment, seafood processing, tourism, entertainment, cosmetics, modern agriculture, and poultry farming. It can replace pesticides to disinfect and sterilize plants—including vegetables and flowers—against various pathogens. For杀菌 purposes, different ozone water concentrations are employed depending on the specific crop and the pathogen involved. Experimental and research results indicate that directly spraying the crops for a duration of 0.5 minutes is sufficient to achieve thorough disinfection and sterilization.

Note: The ozonated water produced by the DJ-W series ozone water generators is a final disinfectant that leaves no residue after disinfection, so there’s no need to rinse again or add other disinfectants.

Product Description and Technical Parameters:

The DJ-W series ozone water generator is a hygienic cleaning and washing product that directly produces ozone-saturated water. It uses a high-speed rotating turbine to create negative pressure, drawing ozone into the space between the turbine and the water. At the same time, the turbine rapidly stirs the ozone and water together, ensuring that the ozone is evenly dispersed throughout the water. The ozone water can be discharged through the provided hose. This device offers a water flow rate ranging from 300 to 3,000 liters per hour and an ozone concentration of 1 to 8.0 ppm (the actual ozone concentration near the spray nozzle typically ranges from 1.0 to 10.0 ppm). This product features a built-in, highly efficient gas-liquid mixing system.

The inlet water pressure must be no less than 0.2 MPa.

DJ-W3030 Specifications:

Input voltage: 100–220VAC

Input power: 800W

Ozone generation method: PEM low-pressure electrolysis

Ozone output: 2400mg/hr

Ozone concentration: 250–285 mg/L

Ozone water production: 300–1000 L/hr

Outlet pressure: 0.1–0.3 MPa

Ozone water concentration for application: 2.3–11.0 mg/L

(Other models omitted)

II. Key Technologies and Innovative Features of the DJ-W Series Ozone Water Generator

1. High-Concentration Ozone Generation Technology. The core component—the PEM electrolysis ozone generator—is a utility model patent owned by our company. It features a modular design, allowing it to be configured into products of various specifications according to customer requirements. The generator’s core electrode is non-consumable, and the water used as a raw material also serves as a coolant, eliminating the need for external auxiliary equipment. This approach simultaneously addresses two key challenges: automatic balancing of the feedwater and efficient heat dissipation from the generator, thereby ensuring the generator’s long-term safe operation. The PEM electrolysis ozone generator can produce a high-concentration ozone-oxygen mixture (18–20% by volume) without generating harmful substances such as nitrogen oxides (NOx).

2. Built-in high-efficiency gas-liquid mixing technology: After ozone is mixed with tap water using a gas-liquid mixing pump to form ozonated water, the mixture is then pumped into a mixing tower for secondary mixing. The mixing tower is equipped with an integrated mixing device that ensures thorough gas-liquid contact. The mixture is then split into two streams: one part is directly supplied through a flowmeter and a regulating valve for immediate use, while the other part is recirculated back into the mixing tower via a circulation pipeline, creating a continuous loop. This process maximizes mixing efficiency and ozone concentration.

3. The prototype testing results indicate that this series of water machines can adjust flow rate and concentration according to different disinfection and sterilization requirements. When the flow rate is increased to 1000 L/h, the ozone mixing efficiency reaches over 95%. The actual ozone concentration near the spray nozzle typically ranges from 2.0 to 10.0 ppm, with a maximum reaching 11.5 ppm. According to a novelty search conducted by scientific and technological experts, no domestic product of similar type has yet reported achieving these performance indicators. Compared with similar products both domestically and internationally, this machine boasts an ozone mixing efficiency that is more than 5% higher, while its volume is only about 50% of those competitors’—thus enabling substantial cost savings and reduced energy consumption.

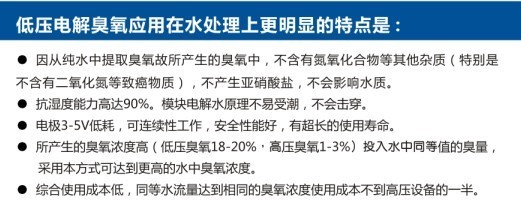

4. Performance and Features of Low-Pressure Electrolysis Type

1) The ozone concentration produced is several times higher by weight compared to the high-voltage corona method (up to 20%).

2) The ozone gas produced contains no nitrogen oxides and no carcinogenic substances.

3) It employs a low-voltage electrolysis principle (3-5V), eliminating any risk of electrical hazards. It does not generate electromagnetic waves or noise, and when operating alongside other precision instruments, it does not cause interference.

4) The ozone generator uses pure water as its gas source and does not require an oxygen source or any additional equipment external to the high-pressure ozone unit during operation. It is easy to operate, safe, and reliable.

5) Low electrode wear, continuous operation capability, and ultra-long service life.

6) It is unaffected by the working environment and temperature, and has a humidity resistance of up to 85%.

7) The pure water self-circulation cooling system eliminates the risk of overheating caused by continuous operation of the equipment.

8) Due to the high ozone concentration produced, using this method with the same amount of ozone introduced into water can achieve a higher ozone concentration in the water.

3. Comparison of Various Performance Indicators Between DJ-Q Type Electrolytic Ozone Generators and Air (Oxygen)-Discharge Ozone Generators

| Performance indicators |

DJ-Q Type Electrolytic Method |

Corona discharge method |

|

| Panel-style |

Tubular |

||

| Air source |

Deionized water |

Air |

Air or oxygen |

| Air source dew point /°C |

0-35 °C |

-60 |

-60 |

| Cooling method |

__ |

Water-cooled or air-cooled |

Water-cooled |

| Operating voltage |

3-5V |

7.6~20 kV |

15~19 kV |

| Power frequency / Hz |

50-60 |

50-500 |

60 |

| Power consumption/kW·h/kg O3 |

50 |

20-30 |

15-19 |

| Dielectric |

Deionized water |

Ceramic sheet (plate) |

Glass tube |

| Air chamber pressure/kPa |

__ |

7-86 |

20-100 |

| Ozone concentration/% (by weight) |

18-20 |

1-3 |

1-3 (air source) 2-6 (oxygen source) |

| Work environment humidity/% |

≤90 |

≤40 |

≤50 |

| Generator electrode life/h |

≥10000 |

≤1000 |

≤3000 |

| Gas composition of the output |

Oxygen + Ozone |

Nitrogen + Ozone + Oxygen + Nitrogen Compounds |

Nitrogen + Ozone + Oxygen + Nitrogen Compounds |

| Pollution status |

None |

Nitrogen oxides and electromagnetic waves |

Nitrogen oxides and electromagnetic waves |

| Related during use Equipment |

No need |

Circulating cooling towers, air dehumidifiers, oil-free pumps |

Circulating cooling tower, air dehumidifier (oxygen cylinder or oxygen concentrator), oil-free pump |

| Operating cost /h Ozone production rate g/h |

0.09 yuan |

0.15 yuan |

0.13 yuan (air source) 0.18 yuan (oxygen source) |

III. Application of the DJ-W Series High-Concentration Ozone Water Generator in Modern Agriculture

Mechanism of Ozone and Ozonated Water in Replacing Pesticides to Control Plant Diseases and Pests: Leveraging ozone's powerful oxidizing properties, it can oxidize and decompose bacterial enzymes such as glucose oxidase and cysteine oxidase. Moreover, ozone disrupts the redox processes involved in bacterial metabolism, thereby inhibiting bacterial growth and reproduction and ultimately leading to bacterial death. Unlike higher animals, plant insects do not rely on blood circulation to deliver oxygen throughout their bodies; instead, their respiratory systems—comprising spiracles and tracheoles—directly facilitate gas exchange between internal tissues and the external environment. Based on this unique physiological characteristic, ozone exerts its toxicological effects by oxidizing and inhibiting various enzymes within insect bodies, disrupting their respiratory and metabolic functions and causing them to suffocate and die. Meanwhile, ozonated water effectively eliminates pathogens and viruses from plant leaf surfaces, creating a pollution-free ecological environment for plants and enabling them to thrive vigorously.

With the development of agricultural production and advances in science and technology, pesticides are playing an increasingly significant role in protecting crops, controlling pests and diseases, improving the human living environment, and combating diseases. Due to the extensive use of pesticides, pesticide residues are inevitably present in agricultural products—among which pesticide residues in fruits and vegetables have attracted particular attention, as they are closely linked to people’s daily lives and health. This poses a serious threat to both public health and personal safety. Theoretically, ozone is a highly effective agent that can oxidize most elements and compounds to their highest oxidation states. It exerts a powerful oxidative decomposition effect on organic substances without generating secondary pollutants and is harmless to humans. Moreover, most pesticides are chlorine- or phosphorus-based compounds; when they react with ozone, they produce oxides of sulfur, phosphorus, carbon, and water, or corresponding acids and water, thereby breaking down into small, non-toxic, and harmless molecules. Ozone water can also degrade pesticides, and the key to effective pesticide degradation lies in the proper concentration of ozone or ozonated water. Experimental evidence has shown that the concentration of ozonated water must exceed 2 mg/L to be effective. Currently, very few ozone equipment and technologies internationally can directly produce ozonated water at such high concentrations. However, our factory’s equipment can generate ozonated water with concentrations as high as 11 mg/L, and the cost for producing one ton of high-concentration ozonated water is only between 1.2 and 2.5 yuan. Our factory has already obtained the Hygiene License for Disinfection Equipment issued by the National Health Ministry for our disinfection products, as well as the Medical Device Approval Certificate (Class I) issued by the Jinhua Municipal Administration for Drug and Medical Device Supervision. In particular, our products have been tested and certified by the Zhejiang Provincial Center for Disease Control and Prevention and the Hubei Provincial Institute for Supervision and Inspection of Electronic Information Products, and the test results are truly remarkable.

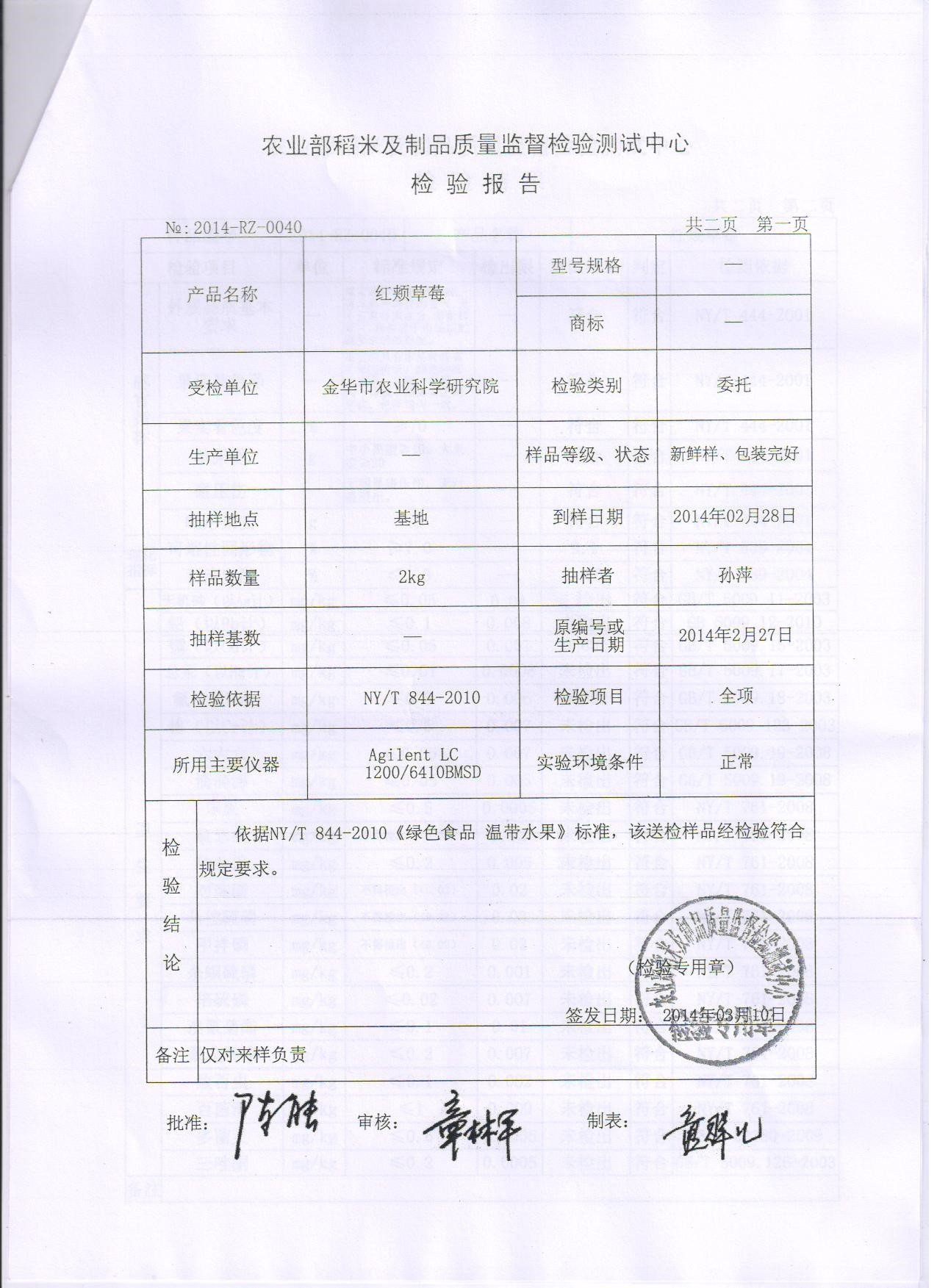

In 2010, our factory conducted a joint trial with the Jinhua City Agricultural Science and Technology Research Institute. We treated strawberries grown in soilless cultivation greenhouses using high-concentration ozone water. During the trial, crops showed significantly better growth and lower incidence of disease compared to plants treated with chemical pesticides—yet no pesticides were used at all. See the photos.

Disinfect using ozonated water.

Disinfect using ozonated water.

Disinfecting with pesticides

Disinfecting with pesticides

On the left is a crop disinfected with ozonated water; on the right is a crop disinfected with pesticides.

Since crops grown without ozone soil disinfection have a higher incidence of disease (due to the use of pesticide disinfection), fifty days after replanting:

On the left is a crop disinfected with ozonated water; on the right is a crop disinfected with pesticides.

100 days after planting, the strawberries enter their ripening stage. Strawberry plants cultivated using high-concentration ozone water for sterilization yield significantly more fruit than those sterilized with pesticides.

On the left is a crop disinfected with ozonated water; on the right is a crop disinfected with pesticides.

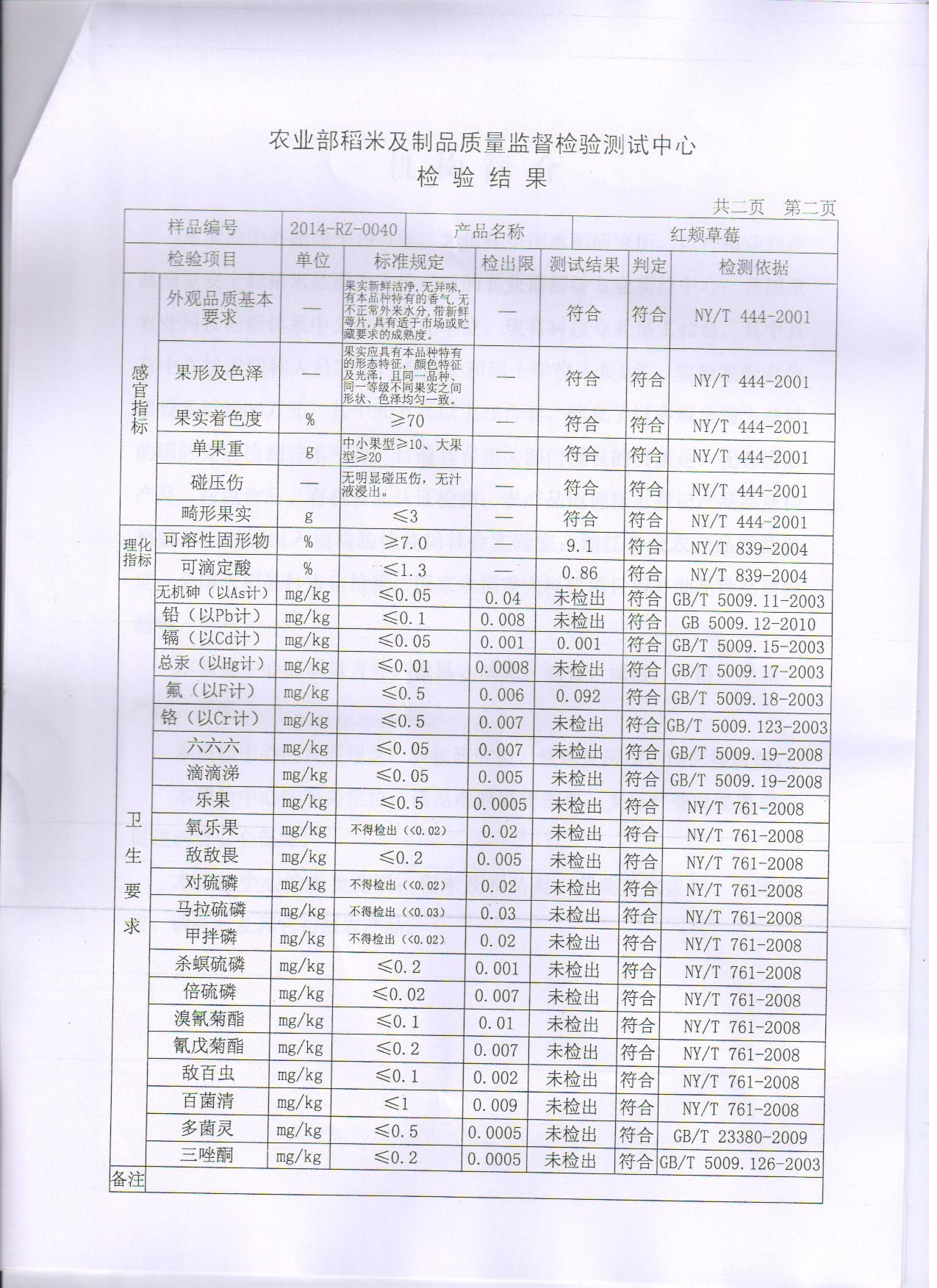

Attachment: Strawberry Testing Report from the Jinhua City Academy of Agricultural Sciences

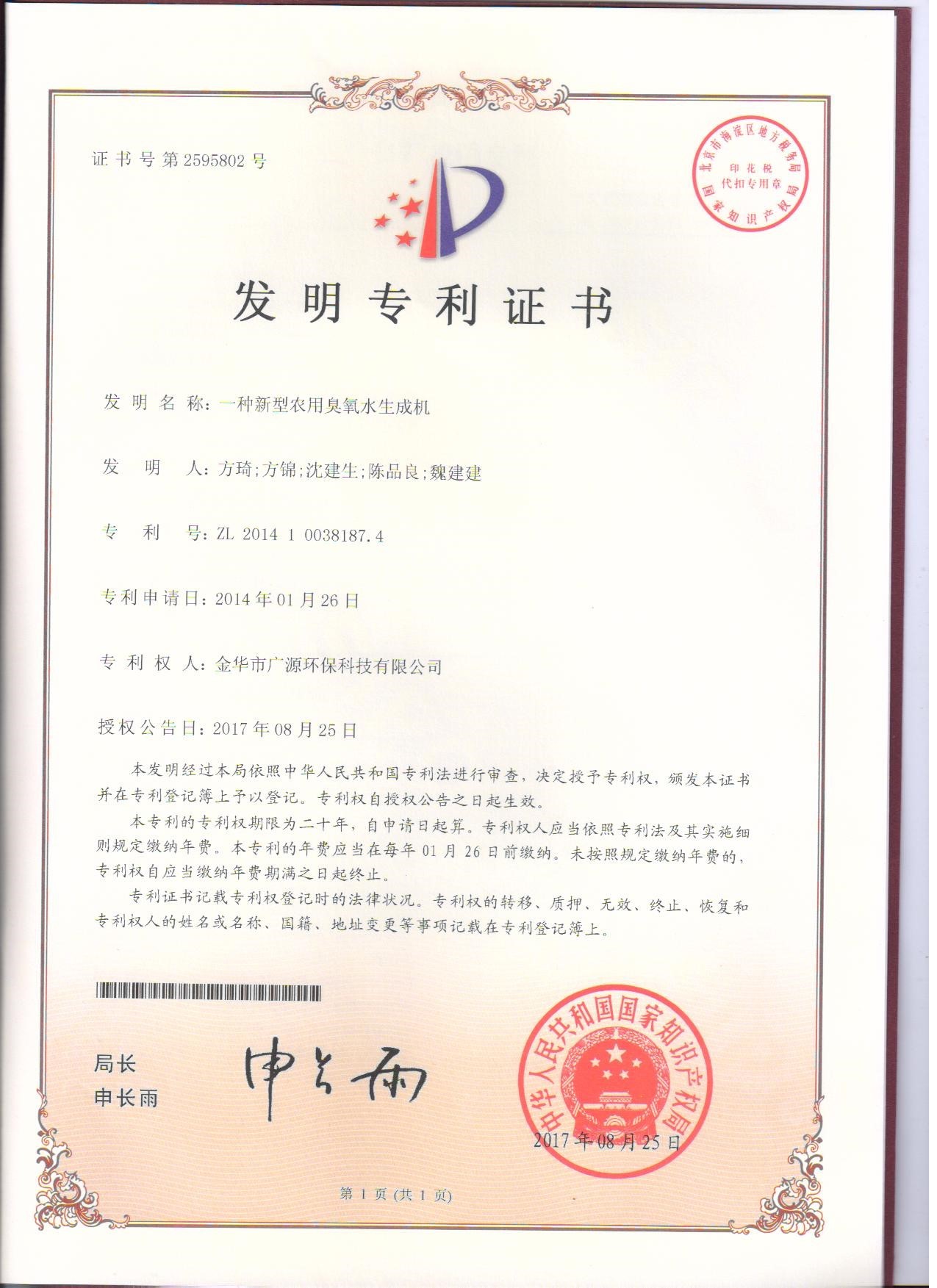

Invention Patent for Agricultural Water Machinery

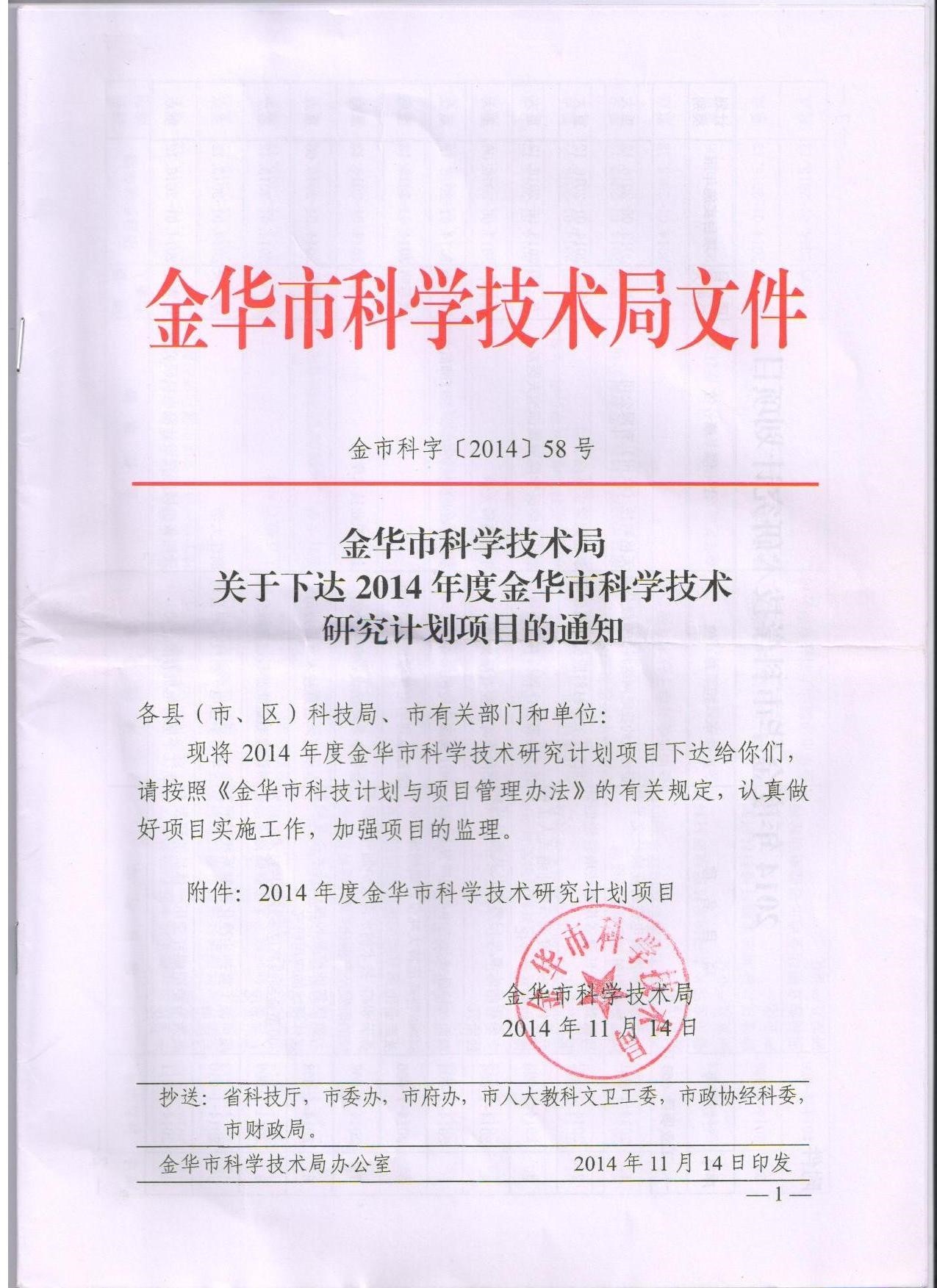

Jinhua City Agricultural Science and Technology Project Documents

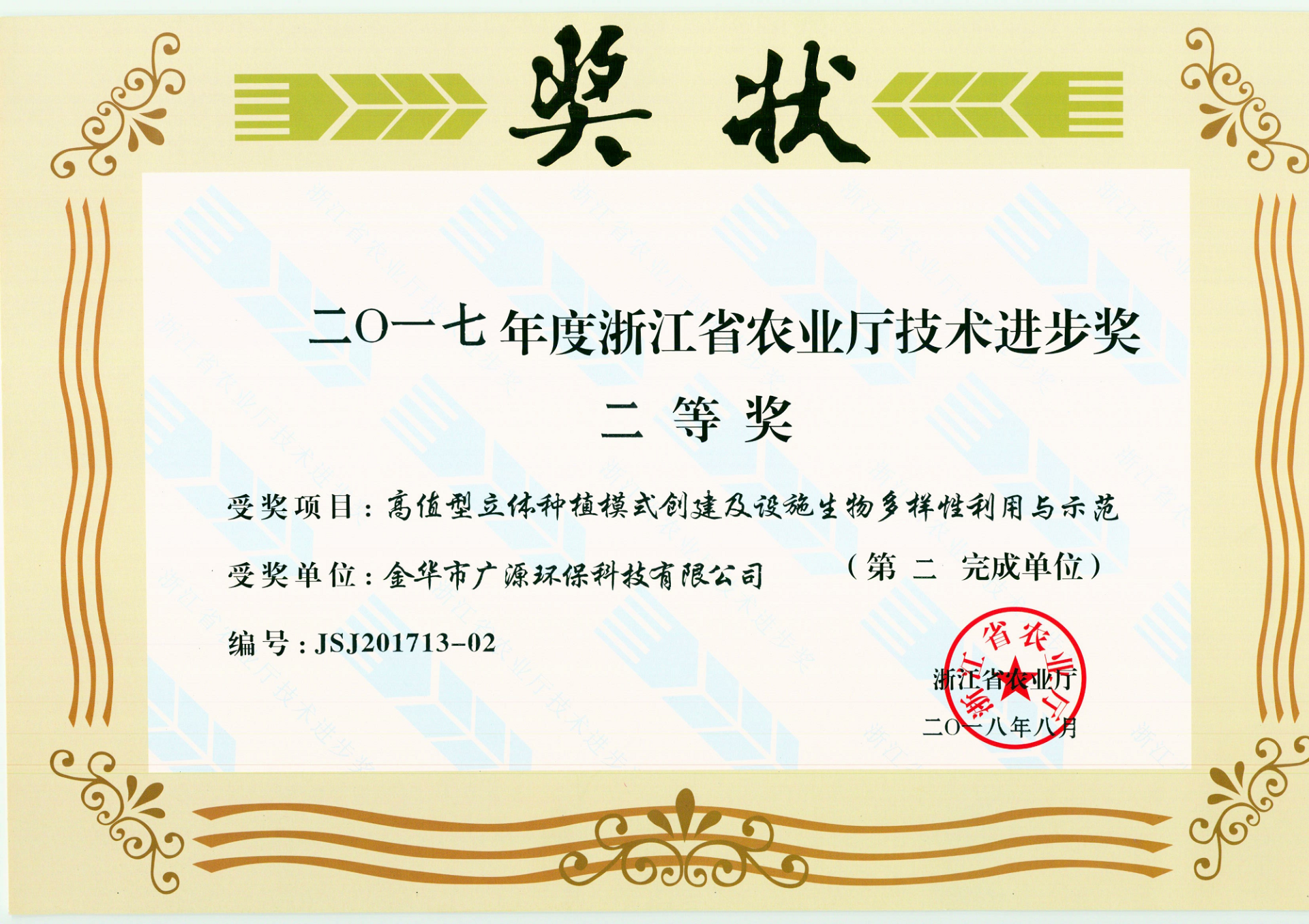

Second Prize Certificate for Scientific and Technological Progress of Zhejiang Province

Manufacturer: Jin China city Wide Source instrument device factory

Supervise Manufacturer: Jinhua Guangyuan Environmental Protection Technology Co., Ltd.

JINHUA GUANYUAN INSTRUMENT FACTORY

Tel: 0579-83239188, 83273699, 83215999, 83256839, 83239338

Fax: 0579-83239166, 84973999 After-sales Service: 0579-83239177, 84971999

Address: No. 1038, Shuxi Road, Jinhua City, Zhejiang Province

http://www.jhgyyq.com/ Email: jhjqkj@163.com

Keywords:

More news

Gather in Shanghai to attend the annual Fishery Expo.

Nationwide sales hotline available 24/7

Address: Building 12, No. 168 Kechang Street, Qiubin Subdistrict, Wucheng District, Jinhua City, Zhejiang Province

E-mail:

Tel:

在线客服添加返回顶部

右侧在线客服样式 1,2,3 1

图片alt标题设置: Guangyuan Environmental

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地