Application of DJ Series Electrolytic Ozone in Edible Mushroom Cultivation Technology

Release date:

2023-03-09

Preface

Mushroom cultivation has long been a relatively stable industry in China. As both the national government and the public increasingly focus on food safety, modern industrial-scale mushroom cultivation—particularly the production of Pleurotus eryngii, Pholiota adiposa, and Pleurotus ostreatus—has entered a critical phase, shifting from widespread development to a greater emphasis on improving production efficiency and product quality. During this transitional period, conventional cultivation techniques have revealed obvious shortcomings. Take, for example, the most crucial aspects of production—sterilization and disease prevention—where new technological breakthroughs are urgently needed to enhance both production efficiency and product quality. Ozone sterilization technology, with its broad-spectrum, highly effective, environmentally friendly, and safe disinfection properties, has now made its way into the mushroom cultivation industry. Leveraging ozone’s unique characteristics for bactericidal, disinfectant, and purification purposes has become a widely adopted high-tech approach in modern mushroom farms both domestically and internationally.

I. Mechanism of Ozone Sterilization and Disinfection

Ozone, also known as active oxygen, is a widely recognized, broad-spectrum, and highly effective bactericidal and disinfectant agent worldwide. Its bactericidal mechanism involves attacking the cell membranes of bacteria, causing damage that disrupts metabolic processes and ultimately leads to bacterial death. As for its antiviral mechanism, it directly destroys ribonucleic acid (RNA) or deoxyribonucleic acid (DNA).

Ozone can kill Escherichia coli, Staphylococcus aureus, Salmonella, Aspergillus flavus, and other microorganisms present in air, water, and on the surfaces of common objects. It can rapidly eliminate bacterial vegetative cells and spores, as well as viruses and fungi. 。

Disinfection is an important step in edible mushroom cultivation. Under the prerequisite of ensuring normal production, directly applying ozone to mushroom production represents currently the most effective approach and method for improving the cultivation environment and disinfecting mushroom inoculation in China.

According to testing by the Zhejiang Provincial Center for Disease Prevention and Control, the bactericidal efficacy of the DJ electrolytic ozone air purifier and disinfectant manufactured by Guangyuan Instrument Factory in Jinhua City, Zhejiang Province, is as follows:

The average kill rate for Staphylococcus aureus was 99.98%.

The mortality rates of natural bacteria were 99.09%, 98.94%, and 98.55%, respectively.

| Test | Duration of action | Control group | Experimental group | ||

| Serial number | (min) | Surviving bacterial count ( cfu/m ³ ) | Natural mortality rate % | Surviving bacterial count ( cfu/m ³ ) | Natural mortality rate % |

| 1 | 0 | 3.50 ×10 5 | — | 3.72 ×10 5 | — |

| 30 | 3.42 ×10 5 | 2.29 | 5.16 ×10 ² | 99.85 | |

| 60 | 3.20 ×10 5 | 8.57 | 42 | 99.98 | |

| 2 | 0 | 3.34 ×10 5 | — | 3.27 ×10 5 | — |

| 30 | 3.25 ×10 5 | 2.69 | 5.72 ×10 ² | 99.82 | |

| 60 | 3.09 ×10 5 | 7.48 | 49 | 99.98 | |

| 3 | 0 | 3.37 ×10 5 | — | 3.49 ×10 5 | — |

| 30 | 3.29 ×10 5 | 2.37 | 6.50 ×10 ² | 99.80 | |

| 60 | 3.13 ×10 5 | 7.12 | 57 | 99.98 | |

| Duration of action | Test Number | Number of control bacterial colonies before disinfection ( cfu/m ³ ) | Number of control bacterial colonies after disinfection ( cfu/m ³ ) | Mortality rate % |

| 60 | 1 | 7.77 ×10² | 7 | 99.09 |

| 2 | 6.64 ×10² | 7 | 98.94 | |

| 3 | 4.83 ×10² | 7 | 98.55 |

II. Differences and Advantages Between Low-Pressure PEM Electrolysis Ozone and Conventional High-Voltage Corona-Ozone Generation

Low-pressure electrolytic ozone generators differ from the high-voltage corona-type ozone generators currently widely used in the market. There are two main methods for humans to develop and extract ozone: one is low-pressure ozone (also known as... PEM The electrolytic method is one approach, while the other is high-pressure ozone generation (also known as the corona discharge or dielectric barrier discharge method). In the low-pressure electrolytic ozone generation process, pure water serves as the feedstock, and a proton-exchange membrane acts as the separator. Under the influence of a low-voltage direct-current electric field, water at a specially designed anode surface loses electrons and is oxidized into ozone. This process requires no auxiliary materials or additives, and the resulting ozone concentration can reach as high as... 20% The ozone byproduct generated is oxygen. O3 + O2 ), without any secondary pollution. In contrast, conventional high-voltage discharge ozone generation uses air or oxygen as raw materials and requires multiple pre-treatment steps, followed by... 15000V Only a high-frequency, high-voltage discharge field on the left and right can produce ozone; the concentration of the generated ozone is low and never exceeds. 6% (Oxygen source), the byproducts of ozone generation include nitrogen, chlorine, nitrogen oxides, and other impurities. N2 + O2 + O3 + NOx ), because the air contains 78% After being subjected to high-voltage discharge, the nitrogen mentioned above reacts with oxygen to form a new substance—nitrogen oxides. Among these, nitrogen dioxide—a major component—is recognized by the World Health Organization as an indecomposable, toxic, and carcinogenic substance. Hence, in the past, when people often said that ozone was harmful, they were mostly referring to the side effects of the high-voltage corona discharge technology used to produce it.

1、 Performance and Features of Low-Pressure Electrolysis

1. The ozone concentration produced is several times higher by weight compared to the high-voltage corona method (reaching up to 20%, whereas the high-voltage method typically achieves only 1-3%).

2. The ozone gas produced does not contain nitrogen oxides (nitric oxide, nitrogen dioxide) and is free of carcinogenic substances.

3. It employs low-voltage electrolysis technology (3-5V), eliminating any risk of electrical hazards. It does not generate electromagnetic waves or noise, and when operating alongside other precision instruments, it does not cause interference.

4. The ozone generator uses pure water as its gas source and, during operation, does not require an oxygen source or any additional auxiliary equipment beyond the high-pressure ozone generator itself. It is easy to operate and safe and reliable.

5. The electrode has low wear, can operate continuously, and boasts an exceptionally long service life.

6. It is unaffected by the working environment and temperature, and has a humidity resistance of up to 85%.

7. Pure water self-circulating cooling eliminates the risk of overheating caused by continuous operation of the equipment.

8. Due to the high ozone concentration generated, using this method with the same amount of ozone introduced into water can achieve a higher ozone concentration in the water.

9.20% High-concentration ozone is used for air disinfection and sterilization. 80% Oxygen is used to improve the quality of the indoor environment and increase the oxygen content of the air.

2、DJ-Q Corona discharge ozone generator with air ( Oxygen ) Comparison of Performance Indicators for Discharge-Type Ozone Generators

|

Performance metrics |

DJ-Q Electrolytic method |

Corona discharge method |

|

| Panel-style |

Tubular |

||

| Air source |

Deionized water |

Air |

Air or oxygen |

| Air source dew point / o C |

0-35 o C |

-60 |

-60 |

| Cooling method |

__ |

Water-cooled or air-cooled |

Water-cooled |

| Operating voltage |

3-5V |

7.6~20 kV |

15~19 kV |

| Power frequency / Hz |

50-60 |

50-500 |

60 |

| Power consumption/kW·h/kgO 3 |

50 |

20-30 |

15-19 9-15 |

| Dielectric |

Deionized water |

Ceramic sheet (plate) |

Glass tube |

| Air chamber pressure/kPa |

__ |

7-86 |

20-100 |

| Ozone concentration/% (weight ratio) |

18-20 |

1-3 |

1-3 air source) 2-6 (oxygen source) |

| Work environment humidity/% |

≤90 |

≤40 |

≤50 |

| Generator electrode life/h |

≥10000 |

≤1000 |

≤3000 |

| Gas composition of the output |

Oxygen + Ozone |

Nitrogen + Ozone + Oxygen + Nitrogen Oxides |

Nitrogen + Ozone + Oxygen + Nitrogen Oxides |

| Pollution status |

None |

Nitrogen oxides and electromagnetic waves |

Nitrogen oxides and electromagnetic waves |

|

Related during use Equipment |

No need |

Circulating cooling towers, air dehumidifiers, oil-free pumps |

Circulating cooling tower, air dehumidifier (oxygen cylinder or oxygen concentrator), oil-free pump |

| Operating cost /h (Ozone production rate g/h) |

0.08 yuan |

0.13 yuan |

0.115 yuan (air) 0.16 yuan (oxygen source) |

III. The Superiority of Ozone Sterilization and Disinfection Technology in Modern Mushroom Cultivation

Traditional sterilization and disinfection methods all have insurmountable limitations, are costly, easily lead to secondary contamination, and can result in residual chemical traces. In contrast, ozone possesses the following advantages: Strong bactericidal efficacy: Ozone's bactericidal ability is comparable to that of peracetic acid and superior to other disinfectants.

1. Broad-spectrum: Suitable for a wide variety of pathogenic microorganisms, it exhibits excellent killing effects against multiple microorganisms, including Escherichia coli, Salmonella, Staphylococcus aureus, hepatitis A and B viruses, and fungi. It can... Quickly and thoroughly eliminates various pathogenic microorganisms from air, surface objects, and drinking water, and effectively removes odors from gases such as ammonia and hydrogen sulfide, providing immediate purification of the space.

2. Strong bactericidal power: Its bactericidal ability is 1.5 to 5 times that of ultraviolet lamps and twice that of chlorine. In water, it kills bacteria 600 to 3,000 times faster than chlorine.

3. Disinfection with no dead corners: Ozone is a gas with good diffusivity. It is easy to embed into dead corners, has a uniform concentration distribution, and can achieve satisfactory disinfection effects on the surfaces of irregular objects as well as in hidden dead corners.

4. Green and environmentally friendly: Ozone can rapidly decompose into oxygen and atomic oxygen, and the atomic oxygen can then combine with itself to form oxygen molecules. Ozone disinfection leaves no toxic residues and causes no secondary pollution. Recognized as a green disinfectant, This is something other disinfectants cannot achieve.

5. Improving the spatial environment: The electrolytic ozone disinfectant is... Purified water ( H2O The oxygen molecules in [the substance] are separated via low-pressure electrolysis with proton exchange technology, and then combined into various forms of oxygen—namely, negative oxygen ions, pure oxygen, and ozone. We can introduce these oxygen forms into the space at timed intervals and in specific quantities, at varying concentrations. Not only do they exhibit extraordinary bactericidal and disinfecting capabilities, as well as the ability to remove odors such as ammonia and benzene, but they also possess... Improves spatial environmental quality and enhances the oxygen content of the air.

6. Abundant raw materials: Ozone is produced using a small amount of pure water, eliminating the need for raw material storage facilities and saving space required for stockpiling.

7. Reduce investment costs: The use of ozone technology can significantly decrease labor input and the use of chemical disinfectants, while also enhancing the automation level of edible mushroom cultivation.

8. Improve survival rate: Effectively prevent and control various fungal diseases, reduce the incidence rate, lower the mortality rate, enhance survival rate, and promote healthy and rapid growth of edible mushrooms.

IV. Hazards of High-Voltage Corona-Ozone in Mushroom Cultivation

Nitrogen oxides are common byproducts generated in high-voltage corona air-source ozone generators. They are formed when nitrogen and oxygen in the air combine under high-voltage corona conditions, producing NOx. As byproducts, NOx typically refers to nitric oxide (NO) and nitrogen dioxide (NO2). Generally, NO reacts with ozone to produce nitrogen dioxide; therefore, in high-voltage corona air-source ozone generators, the primary form of NOx is NO2.

NOX Toxic effects: NO2 It is poorly soluble in water but readily enters the lower respiratory tract, even reaching deep into the lungs. When NO2 reaches the alveoli, it slowly dissolves in body fluids, forming nitrous acid and nitric acid along with their respective salts. These substances, in the form of nitrite and nitrate ions, pass from the lungs into the bloodstream and are distributed throughout the body, causing damage to organs such as the kidneys, liver, and heart. Meanwhile, NO2 itself exerts a strong irritant and corrosive effect on lung tissue, leading to pulmonary edema.

Impaired immune function: Long-term exposure to NO2 not only reduces the phagocytic capacity of alveolar macrophages but also inhibits antibody formation in serum, thereby impairing the body's immune function.

Promoting cancer effects: Animal experiments have shown that NO2 has both pro-cancer and carcinogenic effects.

Since most ozone generators currently used in China employ a high-frequency, high-voltage corona discharge method that uses air as the feedstock to produce ozone, the issue of excessive nitrogen oxide emissions from these ozone generators has become a serious concern. Given that air contains approximately 78% nitrogen, when exposed to high-voltage electrical discharges, nitrogen molecules dissociate into atoms, thereby favoring the formation of highly toxic nitrogen oxides. Moreover, the Chinese market is flooded with a wide variety of ozone equipment, constantly emerging with new models, and product quality varies widely. Many people mistakenly believe that as long as ozone is produced and they can detect its characteristic grassy odor, everything is fine—ignoring the fact that nitrogen oxides represent a hidden killer with enormous health risks to humans. This is particularly true for purification devices that operate on the principle of ozone generation; lacking specialized ozone-generation technology, such devices tend to produce large amounts of nitrogen oxides (NOx) along with ozone. In mushroom cultivation, ozone must be continuously introduced into the production area. However, mushroom greenhouses typically have poor air circulation, especially during winter when doors and windows are tightly sealed to maintain warmth. Unlike pharmaceutical or food factories, which are equipped with air-conditioning, ventilation, and fresh-air systems, this means that ozone—and simultaneously NO2—is continually introduced into the production area. Furthermore, NO2 has been identified by the World Health Organization as an indecomposable carcinogen. As a result, nitrogen oxide levels in mushroom production areas steadily accumulate, posing severe health risks to both mushrooms and workers.

VI. Application of Ozone Disinfection Technology in Mushroom Cultivation

Ozone is a highly effective disinfectant, and it... 100 Various bacteria and molds can effectively kill or inhibit within a short period of time. In the natural environment, ozone can be reduced back to pure oxygen and rapidly convert harmful gases such as sulfur dioxide and carbon monoxide into harmless substances, thereby purifying the air and improving both the growing conditions for edible mushrooms and the working environment for personnel.

The ozone generator employing low-pressure electrolysis technology to produce ozone ions boasts numerous advantages, including a one-time initial investment, long-term usability, and significant energy savings. The key technical points are outlined below.

Everyone knows that microorganisms are ubiquitous in mushroom cultivation substrates, as well as in the air, water, and equipment. When cultivating a fungus, the culture medium, containers, or equipment must be sterilized before use; otherwise, the culture could become contaminated by other fungi or microorganisms, thereby affecting the actual cultivation process. The ozone sterilization method:

1 Air sterilization in the inoculation room and similar areas.

A Mushroom house sterilization In 15 Square meters~ 30 In the indoor space of square meters, set up multi-tier mushroom shelves and complete all preparatory work before starting mushroom cultivation. Install the ozone generator, close windows and doors tightly, then turn it on. 1 Hour, Immediately available 95 Over % sterilization effect (power-on) 15 The minute has reached the expected target. To ensure more thorough sterilization, Can be powered on 30 Minutes~ 60 Minutes. After the machine is shut down, if you don't open the doors or windows, It can keep the air inside the window clean for about a week.

B Culture medium processing Prepare the culture medium according to the original recipe requirements, spread it out on shelves indoors, and once everything is ready, turn on the machine. 1 hours (because the specific gravity of ozone is that of air) 1 . 65 Additionally, by positioning the ozone outlet at a higher location, the ozone generated by the device will naturally descend from the higher point, ensuring that ozone is evenly distributed throughout every corner. Installing a simple pipeline and adding a small vortex air pump would further enhance the effectiveness.

C. Cultivation: Transfer the inoculated fungal strains into the mushroom house, turn on the sterilizer for 30 minutes, then turn it off. Observe the growth of edible mushrooms daily. To ensure an optimal growing environment for the fungal strains, after each time you open the door to observe, you can briefly turn on the sterilizer for 15 minutes, then seal the door again after shutting it down, thus preventing the growth of saprophytic and contaminating fungi and promoting healthy mushroom growth. For ease of operation, the power switch of the sterilizer can be installed in a convenient location outside the mushroom house door. After entering the room and starting the sterilizer, close the door immediately and set the timer to turn it off automatically at the desired time. Alternatively, you can equip the device with our factory’s socket and configure it yourself to set automatic on-and-off times.

D. Many mushroom farms and specialized facilities often employ formaldehyde fumigation for disinfection purposes in order to achieve cleanliness. However, formaldehyde fumigation not only damages equipment such as doors and windows but also causes chemical pollution of the ambient air, posing significant health risks to humans. Moreover, after formaldehyde disinfection, polymers such as potassium permanganate and manganese dioxide tend to form on the surfaces of containers and equipment. A low-pressure electrolytic ozone generator not only effectively sterilizes and improves the indoor environment but can also be used to degrade the pollutants caused by formaldehyde fumigation. According to testing conducted by the Shenzhen Institute of Metrology and Quality Inspection, the formaldehyde degradation rate achieved by a low-pressure electrolytic ozone disinfectant can reach as high as 91%.

2. Sterilization by disinfection machine (cabinet).

Generally used for sterilizing glassware, petri dishes, pipettes, and other items that require sterilization. Simply place the items to be disinfected into the sterilizer with their openings facing upward. After turning on the device, it will automatically shut down and power off after 0.5 to 1 hour, indicating that sterilization is complete. There are two types of electrolytic ozone sterilizers (cabinets): one comes equipped with an ozone destruction device and a drying function, while the other does not have an ozone destruction device. For devices without an ozone destruction device, you must wait until the ozone has fully reverted back to oxygen before opening the cabinet.

3 High-concentration ozone water is used for sterilizing work environments and the surfaces of utensils.

Ozone water is known as "divine water" abroad and can be used directly to disinfect items such as buckets, plates, water tanks, hoses, utensils, conveyor belts, wet surfaces, and CIP equipment. It can also be used for cleaning work areas, production tools, purifying water channels, and washing and disinfecting work clothes. Or disposal of culture media after experiments Compatible materials include stainless steel, plastic, wood, concrete, cement, and more. DJ-W Electrolytic Ozone Water Generator Series It is a highly clean and hygienic spray-washing product that directly generates ozone dissolved in water. The machine The resulting ozonated water can reach concentrations as high as 10 ppm, a level that is rare in China. Moreover, this ozonated water serves as the final disinfectant; after disinfection, it leaves no residue and thus eliminates the need for further rinsing or the addition of other disinfectants.

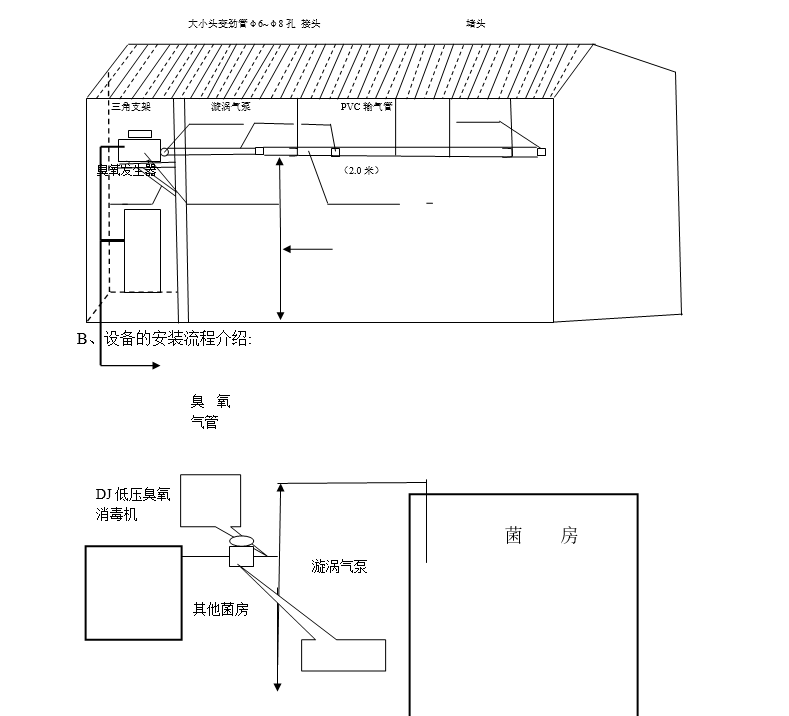

4 Simple ductwork Installation method

A Pipeline laying

Note:

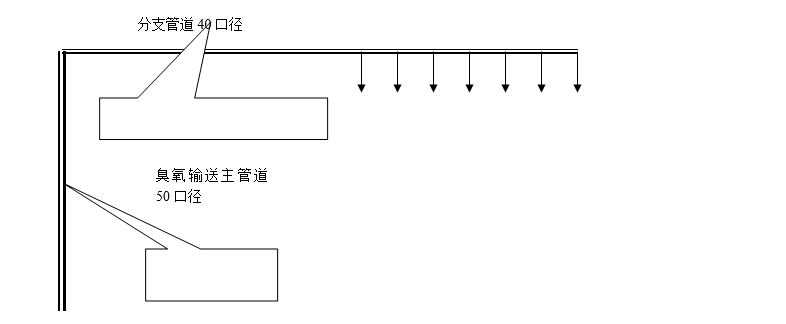

UPVC pipes can be used for pipeline installation. The main pipeline should have a diameter of 50 mm, while the branch pipelines should have a diameter of 40 mm. The pipelines are installed above the workshop walls, with air outlets arranged evenly facing inward. This ensures that ozone is evenly dispersed downward, as shown in the figure below:

Manufacturer: Jin China city Wide Source instrument device factory

JINHUA GUANYUAN INSTRUMENT FACTORY

Phone: 0579-93239188, 83273699, 83238669, 83215999

Fax: 0579-83239166, 84973999 Postal Code: 321001

After-sales service: 0579-83239177 84971999

Address: No. 1038, Shuxi Road, Jinhua City, Zhejiang Province

Address No. 1038, Shuxi Road, Jinhua, Zhejiang

Keywords:

More news

Gather in Shanghai to attend the annual Fishery Expo.

Nationwide sales hotline available 24/7

Address: Building 12, No. 168 Kechang Street, Qiubin Subdistrict, Wucheng District, Jinhua City, Zhejiang Province

E-mail:

Tel:

在线客服添加返回顶部

右侧在线客服样式 1,2,3 1

图片alt标题设置: Guangyuan Environmental

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地