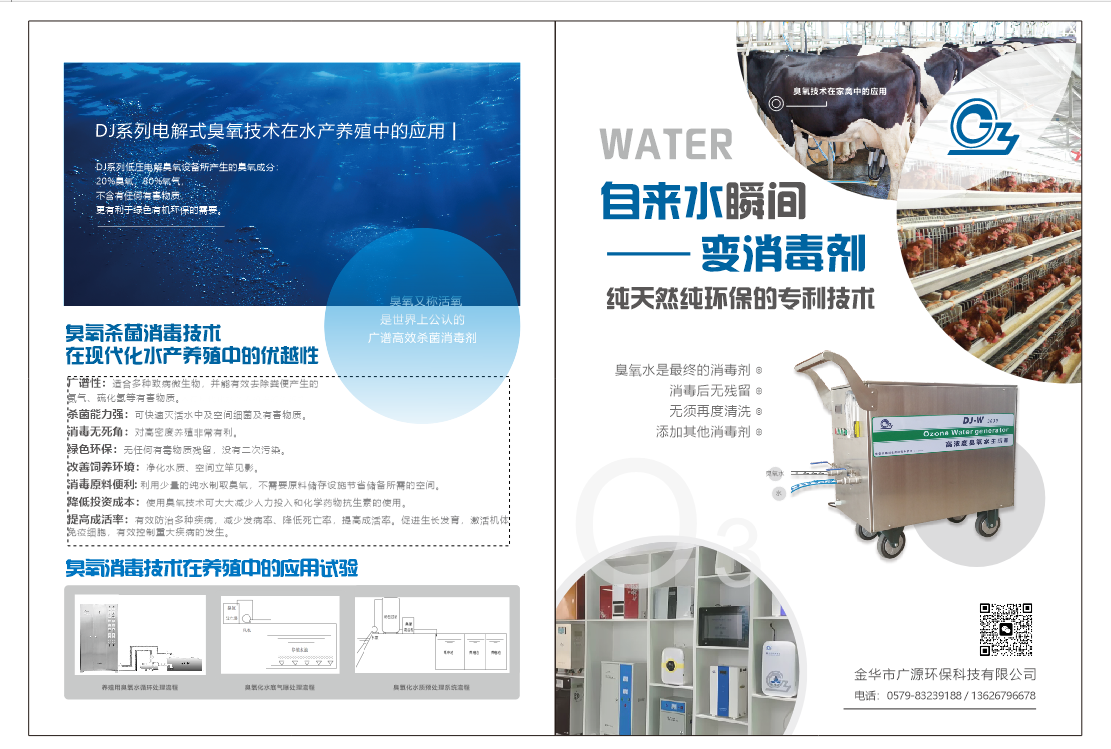

Introduction to the Application of DJ-Series Electrolytic Ozone Technology in Aquaculture

Release date:

2023-03-09

Preface

Aquaculture has long been a relatively stable industry in China, and in recent years, there is still considerable room for growth in per capita fish and meat consumption domestically. However, with the increasing attention paid by both the government and the public to food safety, modern, industrialized aquaculture—especially farmed fish production—is now entering a critical phase, shifting from widespread development toward enhancing production efficiency and product quality. With the development of aquaculture, diseases caused by pathogenic microorganisms in aquatic products occur from time to time, posing a significant threat to the aquaculture industry. In addition to strengthening management practices, eliminating pathogenic microorganisms from both the rearing water and all equipment used has become an important issue for aquaculture facilities. During this transitional period, conventional aquaculture techniques have already revealed obvious weaknesses. Take, for example, the most critical measures for preventing epidemics and diseases in aquatic product production—new technological breakthroughs are urgently needed to enhance both production efficiency and product quality. Ozone disinfection technology, with its broad-spectrum, highly effective, environmentally friendly, and safe disinfection properties, has thus entered the aquaculture industry.

From the perspective of preventive vaccination measures, administering antibiotics and injecting vaccines into fish during routine aquaculture seems beyond reproach. However, neglecting to sterilize, disinfect, and purify the rearing environment means that water contaminated by bacteria, viruses, and other pathogens can readily trigger diseases at any time. Moreover, administering medication not only increases production costs but also leads to the accumulation of antibiotics, which in turn harm the health of farmed fish. Excessive use of chemical drugs can impair the physiological functions of fish and hinder their growth. From a food hygiene standpoint, fish products containing growth hormones and antibiotics pose potential risks to human health. As a powerful oxidizing agent, disinfectant, and catalyst, ozone has not only been successfully applied in water disinfection, water quality improvement, disease prevention in aquaculture systems, and detoxification of red tides, but also—due to its inherent green and environmentally friendly characteristics—is attracting increasing attention.

II. Mechanism of Ozone Sterilization and Disinfection

Ozone, also known as active oxygen, is a widely recognized, broad-spectrum, and highly effective bactericidal and disinfectant agent worldwide. Its bactericidal mechanism involves attacking the cell membranes of bacteria, causing damage that disrupts metabolic processes and ultimately leads to bacterial death. As for its antiviral mechanism, it directly destroys ribonucleic acid (RNA) or deoxyribonucleic acid (DNA). The ozone sterilization device can be used to disinfect biological eggs, sterilize aquaculture water, and sanitize facilities, thereby preventing the intrusion of pathogens. Ozone boasts powerful bactericidal, disinfectant, and water-purifying effects, and it is non-toxic and harmless. It is thus the ideal sterilizing and purifying agent for aquaculture and hatchery production. Its use is of great significance in controlling and preventing diseases in aquatic organisms such as fish, shrimp, sea urchins, river crabs, and soft-shelled turtles, and in improving the ecological environment of aquaculture systems.

Using ozone for larval rearing in aquaculture can save on various disinfectants and antibiotics, reduce water exchange volumes, and decrease fuel consumption. Applying ozone to larval rearing can at least double the survival rate, and a single set of equipment can be used for several years. As a result, this approach significantly cuts down on aquaculture costs while also enabling the production of environmentally friendly, green foods—making it economically advantageous from every perspective. Currently, most countries—including Japan, Europe, and the United States—have widely adopted ozone technology in aquaculture and have banned the use of chemical disinfectants such as chlorides, which can lead to products with excessive chlorine levels entering their markets. Major newspapers frequently report on this issue.

Disinfection is an important step in aquaculture. If disinfection measures are inadequate, it could lead to serious adverse effects on the health of aquatic products. Directly applying ozone to aquaculture production represents currently the most effective approach and method for improving the production environment and ensuring disinfection in aquatic farming within China.

According to testing by the Zhejiang Provincial Center for Disease Prevention and Control, the bactericidal efficacy of the DJ-series electrolytic ozone disinfectors is as follows:

The average kill rate for Staphylococcus albus is 99.98%.

The mortality rates of natural bacteria were 99.09%, 98.94%, and 98.55%, respectively.

Duration of action Test Number Number of control bacterial colonies before disinfection ( cfu/m ³ ) Number of control bacterial colonies after disinfection ( cfu/m ³ ) Forgetting rate %

III. The Superiority of Ozone Sterilization and Disinfection Technology in Modern Aquaculture

III. The Superiority of Ozone Sterilization and Disinfection Technology in Modern Aquaculture

Ozone undergoes a reduction reaction in water at all times, generating highly oxidizing single-atom oxygen (O) and hydroxyl radicals (OH), which instantly decompose organic substances, bacteria, and microorganisms in the water. The hydroxyl radical (OH) is a powerful oxidizing agent and catalyst that triggers a chain reaction in organic compounds. This reaction occurs extremely rapidly, and both single-atom oxygen (O) and hydroxyl radicals (OH) exhibit exceptionally strong bactericidal effects against a wide variety of pathogenic microorganisms. The redox potential of the hydroxyl radical is 2.80 V, comparable to that of fluorine.

Ozone can degrade sulfides, ammonia, and cyanides in water. After reacting with ozone, the toxic sulfides, ammonia, and cyanides are transformed into non-toxic substances, such as H. 2 SO 4 , CO 2 , N 2 substances, thereby achieving the purpose of water purification. Common disinfectants include chlorine, hypochlorous acid (HCLO), and chlorine dioxide (CLO). 2 Sterilization and disinfection using conventional methods are cumulative and require relatively long exposure times. In contrast, ozone water disinfection and sterilization are rapid, with the disinfecting effect occurring instantaneously. Once the ozone concentration in clear water reaches 0.2 to 2 mg/L, bacteria can be killed within 0.5 to 1 minute. When the ozone concentration reaches 4 mg/L, the inactivation rate of the hepatitis B virus can reach 100% within just 1 minute.

Traditional sterilization and disinfection methods all have insurmountable limitations, are costly, prone to secondary contamination, and can leave behind residual chemical traces. In contrast, ozone (O3) naturally reverts back to oxygen (O2). In particular, the ozone generated by the DJ series low-pressure electrolytic ozone equipment consists of 20% ozone and 80% oxygen, containing absolutely no harmful substances, making it even more conducive to green, organic, and environmentally friendly practices.

1. Broad-spectrum: Suitable for a wide variety of pathogenic microorganisms, it exhibits excellent killing effects against multiple microorganisms, including Escherichia coli, Salmonella, Staphylococcus aureus, hepatitis A and B viruses, and fungi. It can... Quickly and thoroughly eliminates various pathogenic microorganisms in air, feed, and drinking water, and effectively removes harmful substances such as ammonia and hydrogen sulfide produced by manure, instantly purifying the rearing environment.

2. Strong bactericidal power: Its bactericidal ability is 1.5 to 5 times that of ultraviolet lamps and twice that of chlorine. In water, it kills bacteria 600 to 3,000 times faster than chlorine.

3. Disinfection with no dead corners: Ozone is readily soluble in water, and when mixed with water, it... It is easy to embed into dead corners, has a uniform concentration distribution, and can achieve satisfactory disinfection effects on the surfaces of irregular objects as well as in hidden dead corners—particularly advantageous for high-density aquaculture.

4. Green and environmentally friendly: Ozone can rapidly decompose into oxygen and atomic oxygen, and the atomic oxygen can then combine with itself to form oxygen molecules. Ozone disinfection leaves no toxic residues and causes no secondary pollution. Recognized as a green disinfectant, This is something no other disinfectant can achieve.

5. Improve the rearing environment: The electrolytic ozone sterilizer is... Purified water ( H2O The oxygen molecules in the solution are separated via low-pressure electrolysis using a proton-exchange membrane technology, and then combined into various forms of oxygen—namely, negative oxygen ions, pure oxygen, and ozone. These oxygen species are precisely and quantitatively mixed into water at different concentrations according to a timed schedule. This process not only boasts exceptional bactericidal and disinfecting capabilities, effectively removing harmful substances such as ammonia and benzene from the water, but also enhances water quality by increasing the dissolved oxygen content in aquaculture water.

6. Abundant raw materials: Ozone is produced using a small amount of pure water, eliminating the need for raw material storage facilities and saving space required for stockpiling.

7. Reduce investment costs: The use of ozone technology can significantly decrease labor input and the use of chemical antibiotics, enhance the level of farming automation, and lower the incidence of diseases in farmed fish.

8. Degradation of harmful substances in water: Due to ozone's strong oxidizing properties, it poses significant hazards to fish in freshwater or seawater used for aquaculture. Nitrite Hydrogen sulfide, ammoniacal cyanide, and other substances can all be oxidized into non-toxic compounds such as NO, SO, and N. At the same time, inorganic substances can also be degraded into substances that are harmless to living organisms, thereby reducing the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) in water.

9. Improve Survival Rate: Effectively prevent and control a variety of diseases, reduce the incidence of diseases in farmed fish, lower mortality rates, enhance survival rates, and promote healthy and rapid growth and development of farmed fish. Activate immune cells in the body, increasing the fish’s own disease resistance by more than three times and effectively controlling the occurrence of major diseases.

IV. Differences and Advantages of PEM Electrolysis-Ozone vs. Conventional High-Voltage Ozone

There are two main methods developed by humans for extracting ozone: one is low-pressure ozone (also known as... PEM The electrolytic method, and the other is high-pressure ozone generation (also known as the corona discharge method). In the low-pressure ozone generation via the electrolytic method, pure water serves as the feedstock, and a proton exchange membrane acts as the separator. Under the influence of a low-voltage direct current electric field, water undergoes electrolysis at a specially designed anode interface. H2O ) By losing electrons, hydrogen and oxygen separate to produce ozone, requiring no auxiliary materials or additives. The resulting ozone concentration can be as high as... 20% The ozone byproduct generated is oxygen. O3 + O2 ), without any secondary pollution. In contrast, conventional high-voltage discharge ozone generation uses air or oxygen as raw materials and requires multiple pre-treatment steps, followed by... 15000V Only a high-frequency, high-voltage discharge field on the left and right can produce ozone; the concentration of the generated ozone is low and never exceeds. 6% (Oxygen source): The ozone byproducts generated include nitrogen, chlorine, nitrogen oxides, and other impurities. N2 + O2 + O3 + NOx ), because the air contains 78% The nitrogen gas mentioned above, after undergoing high-voltage discharge, produces nitrogen oxides—among which nitric oxide and nitrogen dioxide are non-degradable, toxic, and carcinogenic substances. Hence, in the past, when people often said that ozone was harmful, they were usually referring to the side effects of the corona discharge generation technique.

A more noticeable feature of the new low-pressure electrolysis ozone application in aquaculture water disinfection is: 1 , because ozone is extracted from pure water The ozone generated contains no other impurities such as nitrogen oxides (especially no carcinogenic substances like nitric oxide or nitrogen dioxide), and thus does not affect water quality. 2. It has a high resistance to humidity, up to 90%. The modular electrolysis principle is not easily affected by moisture and will not break down. 3. The electrodes operate at a low voltage of 3-5V with minimal power consumption, enabling continuous operation, offering excellent safety performance, and boasting an exceptionally long service life. 4. The ozone concentration produced is high (18-20% for low-pressure ozone, 1-3% for high-pressure ozone). When the same amount of ozone is introduced into water using this method, it can achieve a significantly higher ozone concentration in the water. 5. The overall operating cost is low; for the same water flow rate and achieving the same ozone concentration, the cost is less than half that of high-pressure equipment. 6. While disinfecting, it also provides oxygen enrichment.

2、DJ-Q Corona discharge ozone generator with air ( Oxygen ) Comparison of Performance Indicators for Discharge-Type Ozone Generators

|

Performance indicators |

DJ-Q Electrolytic method |

Corona discharge method |

|

| Panel-style |

Tubular |

||

| Air source |

Deionized water |

Air |

Air or oxygen |

| Air source dew point / o C |

0-35 o C |

-60 |

-60 |

| Cooling method |

__ |

Water-cooled or air-cooled |

Water-cooled |

| Operating voltage |

3-5V |

7.6~20 kV |

15~19 kV |

| Power frequency / Hz |

50-60 |

50-500 |

60 |

| Power consumption/kW·h/kgO 3 |

50 |

20-30 |

15-19 9-15 |

| Dielectric |

Deionized water |

Ceramic sheet (plate) |

Glass tube |

| Air chamber pressure/kPa |

__ |

7-86 |

20-100 |

| Ozone concentration/% (weight ratio) |

18-20 |

1-3 |

1-3 air source) 2-6 (oxygen source) |

| Work environment humidity/% |

≤90 |

≤40 |

≤50 |

| Generator electrode life/h |

≥10000 |

≤1000 |

≤3000 |

| Gas composition of the output |

Oxygen + Ozone |

Nitrogen + Ozone + Oxygen + Nitrogen Compounds |

Nitrogen + Ozone + Oxygen + Nitrogen Compounds |

| Pollution status |

None |

Nitrogen oxides and electromagnetic waves |

Nitrogen oxides and electromagnetic waves |

|

Related during use Equipment |

No need |

Circulating cooling towers, air dehumidifiers, oil-free pumps |

Circulating cooling tower, air dehumidifier (oxygen cylinder or oxygen concentrator), oil-free pump |

| Operating cost /h (Ozone production rate g/h) |

0.08 yuan |

0.13 yuan |

0.115 yuan (air) 0.16 yuan (oxygen source) |

Five The Hazards of High-Voltage Corona-Ozone in Aquaculture

Nitrogen oxides are common byproducts generated in high-voltage corona air-source ozone generators. They are formed when nitrogen and oxygen in the air combine under high-voltage corona conditions, producing NOx. As byproducts, NOx typically refers to nitric oxide (NO) and nitrogen dioxide (NO2). Generally, NO reacts with ozone to produce nitrogen dioxide; therefore, in high-voltage corona air-source ozone generators, the primary form of NOx is NO2.

NOX Toxic effects: NO2 It is poorly soluble in water but readily penetrates the lower respiratory tract, reaching deep into the lungs. When NO2 reaches the alveoli, it slowly dissolves in body fluids, forming nitrous acid and nitric acid as well as their respective salts. These substances, in the form of nitrite and nitrate ions, enter the bloodstream via the lungs and are distributed throughout the body, causing damage to organs such as the kidneys, liver, and heart. At the same time, NO2 itself exerts a strong irritant and corrosive effect on lung tissue, leading to pulmonary edema.

Impaired immune function: Long-term exposure to NO2 can not only reduce the phagocytic capacity of alveolar macrophages but also inhibit the formation of antibodies in serum, thereby impairing the body's immune function.

Promoting cancer effects: Animal experiments have shown that NO2 has both pro-cancer and carcinogenic effects.

Since most ozone generators currently used in China employ a high-frequency, high-voltage corona discharge method that uses air as the feedstock to produce ozone, the issue of excessive nitrogen oxide emissions from these ozone generators has become a serious concern. Given that air contains approximately 78% nitrogen, when exposed to high-voltage electrical discharges, nitrogen molecules dissociate into atoms, thereby preferentially forming highly toxic nitrogen oxides. Moreover, the domestic ozone equipment market today is highly diverse and constantly evolving, with products of varying quality. Many people mistakenly believe that as long as ozone is produced and they can detect its characteristic grassy odor, everything is fine—ignoring the fact that nitrogen oxides represent a hidden killer with enormous health risks to humans. In aquaculture, ozone is continuously introduced into the culture water; thus, every time ozone is added to the rearing water, NO2 is also introduced simultaneously. NO2 has been identified by the World Health Organization as a non-degradable carcinogen. As nitrogen oxide compounds accumulate more and more in the rearing water, they pose severe threats to aquatic products.

In addition, high-voltage corona ozone generators produce large amounts of nitrogen oxides. When these nitrogen oxides dissolve into the aquaculture water along with ozone during water purification and disinfection, they readily form nitrites. ( The most important of nitrogen Mineral is nitrate), This leads to excessive nitrite levels and, when interacting with hormones and antibiotics present in aquatic products, also generates other harmful substances, which are detrimental to the healthy growth of aquatic food.

V. Application of Ozone Disinfection Technology in Aquaculture Experiment

1 The structure of an ozone water treatment system for aquaculture: A complete ozone water treatment system for aquaculture should consist of several components, including a water source, pretreatment of the water source, ozone water treatment, post-treatment of purified water, production water supply, and a recycling and recovery system. The corresponding application process is illustrated in (Figure). 2 )

Figure 2 Ozone Water Circulation Treatment Process for Aquaculture

2 Aquaculture Water Oxygenation and Disinfection Process

Conventional aquaculture water disinfection or oxygenation is primarily achieved through air aeration. Air aeration methods mainly include oxygen enrichment using fan pumps and oxygen generators. However, oxygen generators consume large amounts of energy, have high power requirements, and entail relatively high maintenance and operational costs. Consequently, fan-pump aeration has become the predominant treatment process. Building on the principle of fan-pump aeration, Jianqiao Company directly introduces ozone into the fan ducts, enabling thorough contact between the ozone and the water from below. This rapid oxidation effectively reduces ammonia nitrogen, pathogenic bacteria, and other harmful substances in the water. Meanwhile, as ozone decomposes into oxygen, it helps replenish the dissolved oxygen levels in the water. The process flow is illustrated in the figure. 3:

Figure 3 Ozonated Water Bottom-Aeration Treatment Process

The timing of ozone activation and the dosage amount are critical factors in oxygen-enhanced disinfection. According to research findings, the optimal formula is as follows:

0.5g O 3 / 1m 3 Water / Hour / 4 Next / Heaven

The aquaculture water source is primarily drawn from river channels. To prevent losses caused by the direct use of polluted river water, we have integrated application experiences from multiple regions and implemented pretreatment on the water source. The process flow is shown in the figure. 4:

Figure 4 Ozonation Water Pre-treatment System Process

3、 Water Treatment Experiment in Sea Urchin Larval Rearing At Dalian Bilong Aquaculture Co., Ltd., application DJ — W The ozone water processor was tested under conditions of air temperature. 29 ℃, humidity 85% water temperature 20 ℃; see Table for test results. 1

| Water treatment capacity |

Ammonia content |

Nitrite |

Cash on Delivery |

Number of bacteria |

Sterilization rate |

|

|

11.93 |

3.59 |

0.51 |

1420 |

|

| 5 |

11.62 |

0.56 |

0.50 |

0 |

100 |

| 4 |

3.58 |

0.56 |

0.50 |

0 |

100 |

| 3 |

2.02 |

1.95 |

0.50 |

0 |

100 |

| 2 |

1.92 |

0.84 |

0.50 |

0 |

100 |

The experimental results show that after ozone treatment, ammonia-nitrogen and nitrite are degraded, and the bacterial kill rate is... 100% The water quality has been significantly purified.

When ozone-treated seawater is placed in a culture tank, the growth of Chaetoceros calcitrans is significantly enhanced. The inoculation density is... 10 Ten thousand /ml , it can rapidly proliferate within a week to 100 Ten thousand ~200 Ten thousand /ml You can feed sea urchin larvae.

4 、Application in the Larval Rearing of River Crabs

Applied at the Dahua Seedling Nursery in Dagang District, Tianjin City. DJ-W A series of ozone water processors are undergoing production trials. A total of... 10 Individual nursery ponds, total water volume 400 m3 , including the experimental pool 8 One, water body 320 m3 Comparison pool 2 One, water body 80 m3 The control pond was operated according to the conventional seedling-raising protocol. For the experimental pond, seawater filtered through sand at the nursery was similarly pumped into a storage tank and then passed through... DJ — 20 The ozone processor treats the water, which is then pumped into the nursery pond after temperature adjustment in the transition pond. Daily water exchange volumes are shown in the table. 2

| Metamorphosis stage |

Z 1 |

Z 2 |

Z 3 |

Z 4 |

Z5 |

Large-eyed larva |

| Water exchange rate / Total water volume |

1/16 |

1/8 |

1/6 |

1/4 |

1/4 |

1/4 |

Using ozonated water for river crab larval rearing, from... Z 4 From the larval stage to the nauplius stage, the metamorphosis period can generally be shortened. 2~3 days Moreover, the seedlings are robust and vigorous; the weight of the large-eyed larvae in the experimental group is that of the control group. 111.8% The seedling emergence rate per unit water volume was higher than that of the control group. 60% See table. 3

| Project |

Average seedling density |

Nursery pond water body |

Produce large-eyed larvae |

100 Juvenile with large tail and eyes – body weight |

Weight of a single large-eyed larva |

Average abdominal length of the zoea stage |

| Experiment |

35 |

40 |

28 |

0.46 |

4.63 |

2.07 |

| Comparison |

35 |

40 |

17.5 |

0.42 |

4.14 |

1.64 |

At the Zhanjiang Yongtong Aquaculture Farm, application DJ-Y030 The ozone water processor of this model, due to its relatively small processing capacity, can only be used for semi-closed-loop water circulation in river crab larval rearing. This hatchery has a total of larval-rearing water bodies. 648 m3 Since the nursery is located far from the coast, 15km We need to use a car to transport seawater for seedling cultivation. Usually, we need to haul it every day. 100t Seawater—this open-system seedling-raising method not only increases costs due to the daily intake of seawater, but also causes pollution from the large volume of wastewater discharged. After introducing an ozone water treatment system, the open-loop system has been transformed into a semi-closed loop, reducing the daily seawater transport volume from... 100t Reduce to 40t This not only saves on water transportation costs but also reduces the burden of wastewater discharge.

5 、Application in the Larval Rearing of Macrobrachium rosenbergii

Applied at the Xiamu Farm in Qiongshan, Hainan DJ-Q1616 An ozone-type processor is being used in a closed-loop water circulation trial for the commercial production of giant freshwater prawn larvae. The center is located in the urban area of Qiongshan, and the seawater required for larval rearing must be sourced from... 10km brought in from coastal areas outside the region; therefore, water used for seedling production must be recycled. As a result, the seedling emergence rate in the experimental group was... 3.8 Ten thousand ~4 Ten thousand tails /m 3 , compared to the control group 2.5 Ten thousand ~3 Ten thousand /m3 Higher than 25.0%~34.2% 。

6 、Applications in the cultivation of live feed organisms After settling the seawater and sand filtration, in... 10 Add per cubic meter of seawater under conditions around ℃. 1~2g Ozone can completely eliminate protozoa, algae, and bacteria from water. Water treated in this way can be directly used to culture microalgae and rotifers. , Moreover, there is no need to use other drugs for treatment, nor is prolonged aeration required. Taking the cultivation of Phaeodactylum tricornutum as an example, the comparative test results with conventional methods are shown in the table. 4

| Grouping |

|

|

Time |

|

|

|

| Conventional method |

100 |

120 |

140 |

165 |

180 |

190 |

| With ozone water |

98 |

130 |

150 |

190 |

210 |

230 |

| With ozone water |

110 |

130 |

150 |

190 |

210 |

230 |

| With ozone water |

110 |

135 |

154 |

225 |

240 |

250 |

|

|

|

|

|

|

|

|

In addition, using ozonated water for brine shrimp hatching can increase the hatching rate by more than 10%. When using ozonated water to hatch channel catfish, the hatching process becomes significantly simpler. By replacing only about one-fourth of the total water volume with ozonated water each day, the hatching rate can reach over 95%, and the resulting fry exhibit robust health. The step of washing eggs with malachite green is eliminated. Furthermore, when using ozonated water for raising tilapia fry, the experimental group showed a growth rate 1.3 times faster than the control group within 30 days. In the cultivation of California bass fry using ozonated water, the fry were initially stocked at a size of 0.7 cm. By the time of harvest, the average size of the experimental-group fry had reached 2.65 cm, with a survival rate of 78.6%, whereas the control group had an average size of 2.57 cm and a survival rate of only 43.8%.

Note: The equipment models listed above are originally from Jinhua Jianqiao Company.

Some technical data were provided by Jinhua Jianqiao Company.

Manufacturer: Jin China city Wide Source instrument device factory

JINHUA GUANYUAN INSTRUMENT FACTORY

Telephone (Tel): 0579-83215999, 83238667, 83273699, 83238669

Fax: 0579-84973999 Postal Code: 321001

After-sales service: 0579-84971999

Address: No. 255, Shuanglong North Street, Jinhua City, Zhejiang Province

Address No. 1038, Shuxi Road, Jinhua, Zhejiang

Keywords:

More news

Gather in Shanghai to attend the annual Fishery Expo.

Nationwide sales hotline available 24/7

Address: Building 12, No. 168 Kechang Street, Qiubin Subdistrict, Wucheng District, Jinhua City, Zhejiang Province

E-mail:

Tel:

在线客服添加返回顶部

右侧在线客服样式 1,2,3 1

图片alt标题设置: Guangyuan Environmental

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地