Share to:

DJ-Y2020QX2

This product is widely used in industries such as pharmaceuticals, healthcare, food processing, drinking water treatment, seafood processing, tourism, entertainment, cosmetics, and poultry farming. It can also be applied for surface disinfection in venues like hotels, restaurants, cafeterias, hospitals, and livestock farms.

If you're interested in our products,Please contact us.

Product Categories

Keywords:

Details

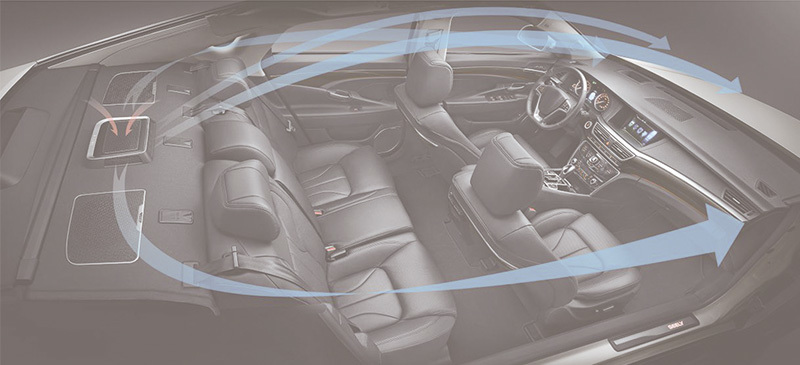

Suitable for removing interior trim pollutants, disinfecting and sterilizing air conditioning systems, and eliminating various odors inside the vehicle.

I. Low-pressure electrolytic ozone generator

Water is the source of all things. We employ a low-pressure electrolysis technology that separates oxygen molecules from pure water (H₂O) through a proton-exchange membrane, producing various forms of oxygen—including negative oxygen ions, pure oxygen, and ozone. Backed by advanced oxygen-extraction technology, we precisely and quantitatively release these polymorphic forms of oxygen into the space at specific intervals and concentrations, tailored to actual usage needs. This comprehensive treatment process—from sterilization and disinfection to the removal of methanol and benzene, as well as odor elimination and oxygen enrichment for fresher air—creates a healthy, safe, and comfortable living and working environment for you.

Currently, there are two main technologies for generating ozone: one is the high-voltage corona discharge method (high-voltage discharge type), which uses air as its raw material. In this method, a dielectric material is placed between two parallel high-voltage electrodes, maintaining a certain discharge gap. When a high voltage is applied across the electrodes, the heat generated excites oxygen molecules in the air, causing them to gain energy and collide with each other, thereby forming ozone. The corona discharge method produces ozone using air as a feedstock; however, since air contains more than 78% nitrogen, under high-voltage conditions, nitrogen reacts with oxygen to form a new substance—nitrogen dioxide. Nitrogen dioxide is internationally recognized as a toxic substance and is considered one of the factors contributing to cancer development. Moreover, the high-voltage corona discharge technology has limitations in producing high-concentration ozone; typically, the weight-based ozone concentration ranges from 1% to 3%. The other method is the low-voltage electrolysis method (low-pressure water-splitting method), which uses water as its raw material and employs solid-state noble-metal polymer electrolytes. By performing low-voltage electrolysis on water (H₂O), oxygen is separated to produce ozone. The resulting ozone concentration can reach as high as 18% to 20% by weight, and the gas produced contains only oxygen with no harmful substances whatsoever. Low-voltage electrolysis ozone generators are suitable for small- and medium-sized equipment; although their output volume is relatively modest, their ozone concentration is exceptionally high. Ozone concentration is conventionally expressed as a volume percentage. For the corona discharge method, the ozone concentration from air sources typically ranges from 1% to 3%, while that from oxygen sources ranges from 2% to 6%. In contrast, the ozone concentration from low-voltage electrolysis can reach 18% to 20%. Domestically, ozone concentrations are commonly reported in units such as mg/L or mg/m³. Specifically, the ozone concentration from air sources via the corona discharge method ranges from 10 to 40 mg/L, from oxygen sources from 20 to 80 mg/L, and from pure water sources via electrolysis from 250 to 280 mg/L. Low-voltage electrolysis ozone generators have low power consumption—operating at just 3 to 5 volts—and are safe, stable, and reliable. Notably, the ozone gas they produce contains neither nitrogen oxides nor volatile organic compounds, as specified by national environmental monitoring standards. As a result, these generators have gained widespread popularity among both domestic and international customers.

II. Selection of Ozone Generators

To select an appropriate ozone generator, it’s essential to understand the evaluation criteria for ozone generators. Generally, the most fundamental indicators for evaluating an ozone generator include: ozone output, ozone concentration, operating costs, reliability, service life, stability performance, and environmental protection standards.

Currently, most ozone generators in China employ a high-frequency, high-voltage corona discharge method that uses air as the feedstock to produce ozone. A serious issue arising from this type of ozone generator is the excessive production of nitrogen oxides. Since air contains more than 78% nitrogen, when exposed to a high-voltage discharge environment, nitrogen molecules dissociate into atoms, which then preferentially combine with oxygen to form highly toxic nitrogen oxides—NOx. In particular, the NOx produced by air-source ozone generators using the high-voltage corona discharge method mainly consists of nitrogen dioxide (NO₂). Specifically: 1. NO₂ is poorly soluble in water and readily penetrates the lower respiratory tract, reaching deep into the lungs. Once it reaches the alveoli, NO₂ slowly dissolves in body fluids, forming nitrous acid, nitric acid, and their respective salts. These substances, in the form of nitrite and nitrate ions, enter the bloodstream via the lungs and are distributed throughout the body, causing damage to organs such as the kidneys, liver, and heart. Moreover, NO₂ itself exerts a strong irritant and corrosive effect on lung tissue, leading to pulmonary edema. 2. Impairment of immune function: Long-term exposure to NO₂ not only reduces the phagocytic capacity of alveolar macrophages but also inhibits the formation of antibodies in the serum, thereby compromising the body’s immune defenses. 3. Carcinogenic effects: Animal experiments have shown that NO₂ has both promoting and carcinogenic effects. Additionally, the ozone generator market in China today is highly diverse and constantly evolving, with products varying widely in quality. Many people mistakenly believe that as long as ozone is produced, everything is fine, overlooking the fact that nitrogen oxides—the silent killer posing a tremendous threat to human health—are often overlooked. This is especially true for low-priced ozone generators, whose simple configurations and inferior materials make them far more likely to generate large amounts of nitrogen oxides (NOx) alongside ozone. In many pharmaceutical cleanrooms, ozone disinfection is performed frequently; some even use ozone during ongoing production processes—particularly in facilities with inadequate ventilation or fresh-air supply systems. As a result, nitrogen oxides tend to accumulate in clean zones, posing severe health risks to workers. Therefore, selecting a high-quality ozone generator is extremely important.

III. Advantages of Low-Pressure Electrolytic Ozone Generation

Performance and Features of Low-Pressure Electrolysis

1. The resulting ozone concentration, by weight, is several times higher than that produced by the high-voltage corona method (reaching up to 20%).

2. The ozone gas produced contains no nitrogen oxides and no carcinogenic substances.

3. It employs a low-voltage electrolysis principle (3–5V), eliminating any risk of electrical hazards. It does not generate electromagnetic waves or noise, and when used alongside other precision instruments, it does not cause interference.

4. The ozone generator uses pure water as its gas source and does not require an oxygen source or any additional auxiliary equipment external to the high-pressure ozone unit during operation, making it easy to operate and safe and reliable.

5. Low electrode wear, continuous operation capability, and ultra-long service life.

6. It is unaffected by the working environment and temperature, with a humidity resistance of up to 85%.

7. The pure water self-circulation cooling system eliminates the risk of overheating caused by continuous operation of the equipment.

8. A 20% high-concentration ozone is used for air disinfection and sterilization. An 80% oxygen concentration is used to improve indoor air quality and increase the oxygen content of the air.

Performance Indicators and Comparison of DJ-Y Type Electrolytic Ozone Generators vs. Air (Oxygen)-Discharge Ozone Generators

| Performance metrics |

DJ-Y Type Electrolysis Method |

Corona discharge method |

|

| Panel-style |

Tubular |

||

| Air source |

Deionized water |

Air |

Air or oxygen |

| Cooling method |

__ |

Water-cooled or air-cooled |

Water-cooled |

| Operating voltage |

3~5V |

7.6~20 kV |

15~19 kV |

| Power consumption/kW·h/kg O₃ |

50 |

20~30 |

15~19 |

| Dielectric |

Deionized water |

Ceramic sheet (plate) |

Glass tube (quartz) |

| Air chamber pressure/kPa |

__ |

7~86 |

20~100 |

| Ozone concentration/% (weight ratio) |

18~20 |

1~3 |

1~3 (air source) 2~6 (oxygen source) |

| Work environment humidity/% |

≤90 |

≤40 |

≤50 |

| Generator electrode life/h |

≥10000 |

≤1000 |

≤3000 |

| Gas composition of the output |

O₃ + O₂ |

N + O₂ + O₃ + NOx |

N + O₂ + O₃ + NOx |

| Pollution status |

None |

Nitrogen oxides and electromagnetic waves |

Nitrogen oxides and electromagnetic waves |

| Relevant equipment in use |

No need |

Circulating cooling towers, air dehumidifiers, oil-free pumps |

Circulating cooling tower, air dehumidifier (oxygen cylinder or oxygen concentrator), oil-free pump |

| Operating cost /h (Ozone production rate g/h) |

0.08 yuan |

0.135 yuan |

12 yuan (air source) 0.16 yuan (oxygen source) |

IV. Design Parameters for the Application of the New GMP Cleanroom Version of Electrolytic Ozone Generators

| To request Cleanliness Level |

Ozone Device model |

Design Ozone concentration |

Ozone Disinfection time |

Effective space (volume) / m³ |

|

Grade A |

DJ-Y1010 |

30ppm |

120min |

20 |

| DJ-Y2020 |

40 |

|||

| DJ-Y4040 |

80 |

|||

| DJ-Y8080 |

160 |

|||

| DJ-Y1616 |

320 |

|||

| DJ-Y2424 |

480 |

|||

| DJ-Y3232 |

640 |

|||

|

Grade B |

DJ-Y1010 |

20ppm |

100min |

30 |

| DJ-Y2020 |

60 |

|||

| DJ-Y4040 |

120 |

|||

| DJ-Y8080 |

240 |

|||

| DJ-Y1616 |

480 |

|||

| DJ-Y2424 |

720 |

|||

| DJ-Y3232 |

960 |

|||

|

Class C |

DJ-Y1010 |

10ppm |

90min |

50 |

| DJ-Y2020 |

100 |

|||

| DJ-Y4040 |

200 |

|||

| DJ-Y8080 |

400 |

|||

| DJ-Y1616 |

800 |

|||

| DJ-Y2424 |

1200 |

|||

| DJ-Y3232 |

1600 |

|||

|

Class D |

DJ-Y1010 |

6ppm |

80min |

80 |

| DJ-Y2020 |

160 |

|||

| DJ-Y4040 |

320 |

|||

| DJ-Y8080 |

640 |

|||

| DJ-Y1616 |

1280 |

|||

| DJ-Y2424 |

1920 |

|||

| DJ-Y3232 |

2560 |

*Low-pressure ozone generators can be arbitrarily combined according to the number of modules, or customized to meet customer requirements.

Previous

Next

Get a quote

Related Products

Nationwide sales hotline available 24/7

Address: Building 12, No. 168 Kechang Street, Qiubin Subdistrict, Wucheng District, Jinhua City, Zhejiang Province

E-mail:

Tel:

在线客服添加返回顶部

右侧在线客服样式 1,2,3 1

图片alt标题设置: Guangyuan Environmental

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地