Share to:

Hose

This product is widely used in industries such as pharmaceuticals, healthcare, food processing, drinking water treatment, seafood processing, tourism, entertainment, cosmetics, and poultry farming. It can also be applied for surface disinfection in venues like hotels, restaurants, cafeterias, hospitals, and livestock farms.

If you're interested in our products,Please contact us.

Product Categories

Keywords:

Details

Currently, the two main ozone-generation technologies in use are the corona discharge method and the electrolysis method.

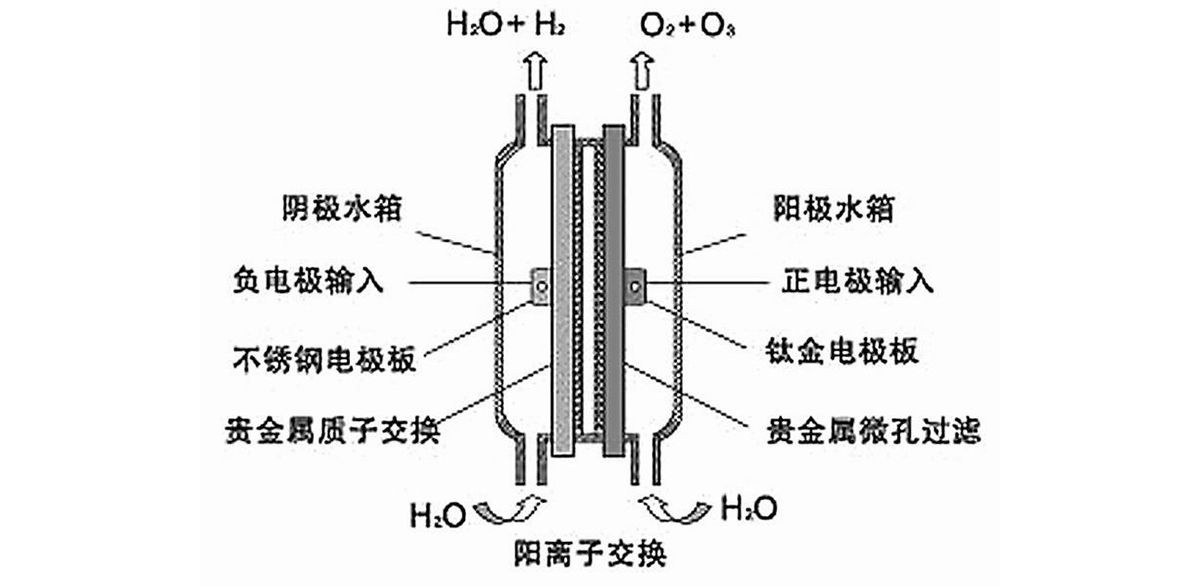

High-voltage corona method (high-voltage discharge method): This method uses air as its raw material and maintains a certain discharge gap between two parallel high-voltage electrodes separated by a dielectric medium. When a high voltage is applied across the electrodes, the heat generated excites oxygen molecules in the air, enabling them to gain energy and collide with each other, thereby forming ozone. The corona method produces ozone using air as a gas source. Since air contains more than 78% nitrogen, under high-voltage conditions, nitrogen reacts with oxygen to form a new substance—nitrogen dioxide. Nitrogen dioxide is internationally recognized as a toxic substance and is one of the factors contributing to the development of cancer. Moreover, the technology used in the high-voltage corona method also limits the possibility of producing high-concentration ozone; typically, the weight-based concentration of ozone produced by this method ranges from 1% to 3%. Low-pressure electrolysis method (low-pressure water-splitting method): This method uses water as its raw material and employs solid-state noble-metal polymers as electrolytes. By performing low-voltage electrolysis on water (H₂O), oxygen is separated to produce ozone. The resulting ozone has a weight-based concentration as high as 18% to 20%, and the accompanying gas is pure oxygen—with no harmful substances whatsoever.

The PEM electrolysis ozone generator uses pure water as its feedstock and a solid-state noble-metal polymer as the electrolyte. Employing a cation-exchange mode, it produces ozone via low-voltage electrolysis without requiring any auxiliary materials or additives. The resulting ozone concentration can reach as high as 20% (by weight, equivalent to 250–280 mg/L). The accompanying gas produced is oxygen, with no secondary pollution whatsoever. In contrast, conventional high-voltage corona discharge ozone generators use air or oxygen as feedstock and require multiple pre-treatment steps. They rely on a high-frequency, high-voltage electric field of around 3,600 V to generate ozone, with the maximum achievable ozone concentration limited to no more than 10%. The byproducts of this process include nitrogen, oxygen, nitrogen oxides, and other impurities; among these, nitrogen oxides are non-degradable, toxic, and carcinogenic substances. The emergence of the third-generation ozone technology—the PEM low-voltage electrolysis ozone generation technology—has greatly expanded the application scope of ozone. This technology overcomes all the drawbacks inherent in traditional high-voltage corona discharge methods. Its core electrode is non-consumable, resulting in lower operating costs. Moreover, the ozone concentration produced by this method is more than six times higher than that achieved by conventional high-voltage corona discharge systems. Importantly, the ozone generated by this method contains no harmful substances such as nitrogen oxides and causes no secondary pollution whatsoever, making it a truly low-carbon, energy-efficient, and environmentally friendly product. Consequently, its application fields have become much broader, and it represents an inevitable trend in the development of ozone production technologies.

Third-generation ozone generation technology

Nitrogen-free compounds, no electromagnetic interference, low usage costs, and excellent safety performance.

1. Product process structure

Figure 1. PEM electrode

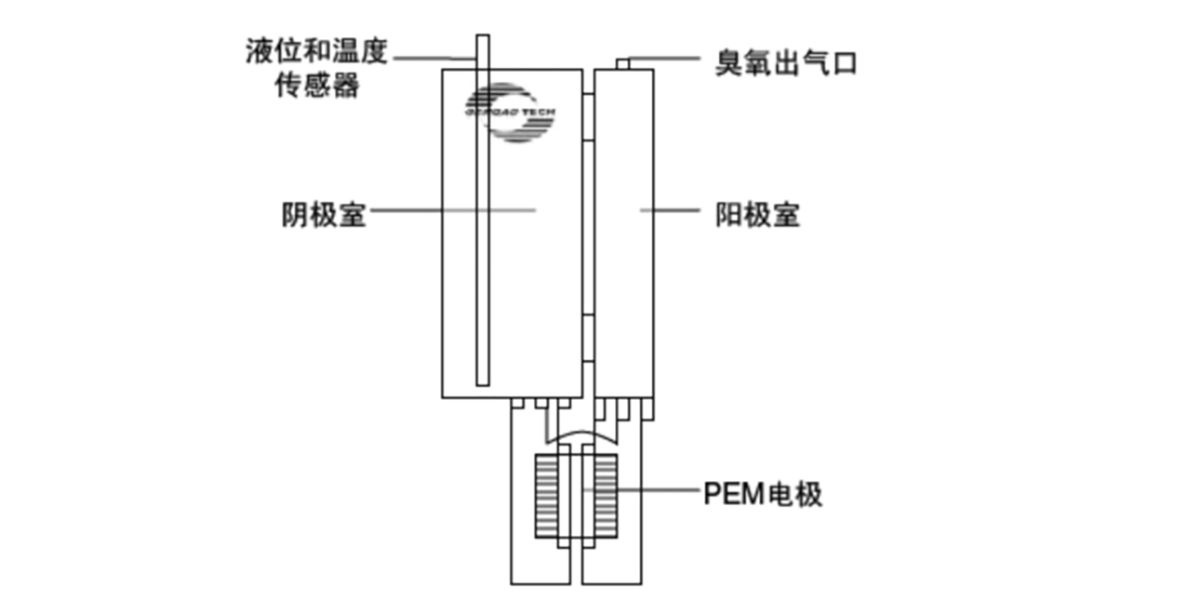

Figure 2. PEM Electrolysis Ozone Generation System

2. Precautions

2.1 PEM Electrode

The PEM electrode should be installed and activated immediately after the sealing plug is removed. The positive and negative electrodes of the product must be kept from short-circuiting; otherwise, their service life will be affected. The anode and cathode water tanks must be completely filled with deionized water (pure water or distilled water) to prevent drying, which could cause the ion-exchange membrane to fail. The electrodes must be used with a dedicated constant-current power supply. For a single electrode, the power supply should provide an output of 3–5 V / 12 A / 15–30% AC ripple. When electrodes are connected in series, the voltage requirement increases proportionally with the number of electrodes. Otherwise, the electrodes will either fail to generate ozone or become damaged and fail due to breakdown.

The electrolytic feedstock used for ozone generation in PEM electrodes is deionized water with a conductivity of ≤5 µS/cm (purified water or twice-distilled water). It is strictly prohibited to use water that does not meet these requirements as the electrolytic feedstock, as this could cause electrode short circuits, shorten the electrode's service life, or lead to its failure and damage.

2.2 Installation and Connection

PEM electrodes are suitable for installation and use in ozone equipment designed to produce ozone gas or ozonated water; as long as they are properly connected to the corresponding system, they can generate high-concentration ozone.

2.2.1 Installation Requirements for PEM Electrodes in Devices Primarily Designed for Ozone Gas Generation:

Related attachments

Cathode water tank / Anode water tank / Connecting pipe / Dedicated power supply / Relay

The cathode water tank shall have a capacity of at least 1 liter and be made from non-conductive materials with excellent corrosion resistance and heat dissipation performance.

The anode water tank shall have a capacity of at least 200 ml and be made from a non-conductive material with excellent heat dissipation properties and resistance to strong oxidation.

The connecting pipe has an inner diameter of Ø6–8 mm and must be made from a material that is tough, highly resistant to strong oxidation, and has a low coefficient of thermal deformation.

Attention: When connecting the PEM ozone generator, be sure not to reverse the anode and cathode connections. The outlet of the generator’s anode and cathode should be as vertically aligned as possible with the upper anode and cathode water tank; the shorter the distance between them, the smoother the gas output and the longer the generator’s service life and higher its efficiency.

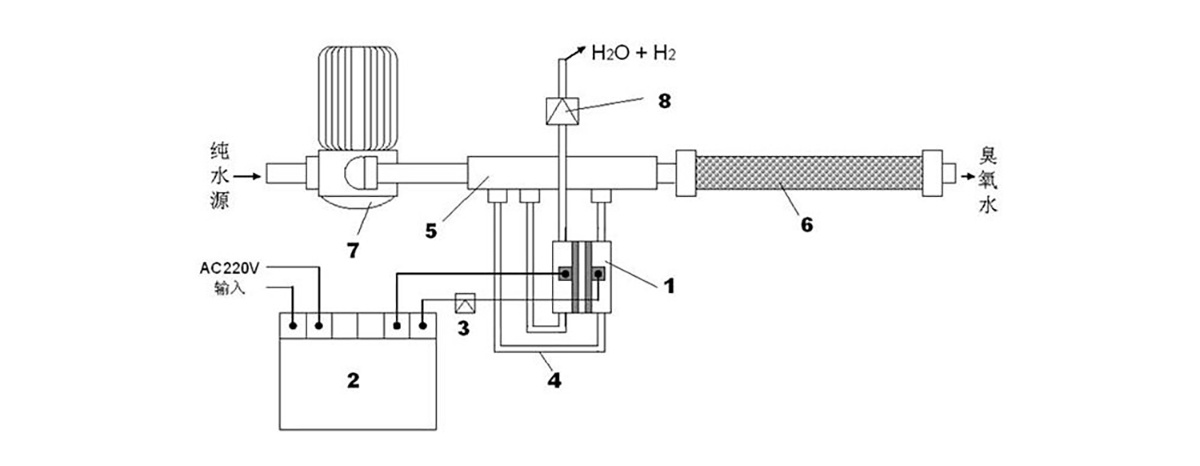

Figure 3. Wiring Diagram of the PEM Electrolysis Ozone Generation System

1. PEM electrode 2. Hose 3. Cathode water tank 4. Anode water tank 5. Constant-current switching power supply 6. Relay

2.2.2 Installation Requirements for PEM Electrodes in Equipment Primarily Designed for Producing Ozonated Water:

Related attachments

Purified water source / Booster pump / Multi-way pipe / Connecting pipe / Mixing device / Dedicated power supply / Relay

Purified water sources should be supplied via RO reverse osmosis units or by bottled purified water and distilled water.

Booster pumps should preferably be self-priming pumps with an outlet pressure of ≥4 kg.

Multi-port water pipes should use standard water supply pipes made of stainless steel or UPVC.

The connecting pipe has an inner diameter of Ø6–8 mm and must be made from a material that is tough, highly resistant to strong oxidation, and has a low coefficient of thermal deformation.

The mixing device should adopt either a bridge-plate multi-stage turbulent mixing method or a packed porous serial-flow tube mixing method. The bridge plates or packing materials should be made of ceramic or stainless steel.

Attention: When connecting the PEM ozone generator, be sure not to reverse the anode and cathode. The outlet of the generator’s anode and cathode should be as vertically aligned as possible with the upper water pipe; the shorter the distance between them, the smoother the gas output and the longer the generator’s service life and higher its efficiency. The ozone-water outlet should not have any resistance or valves, otherwise backflow of water could damage the generator.

Figure 4. Connection Diagram of the PEM Electrolysis Ozone Water Generation System

Legend: (1) PEM Ozone Generator (2) Dedicated Constant-Current Switching Power Supply (3) 40A/12V DC Relay (4) Connecting Pipe (5) Multi-Port Water Pipe (6) Mixing Device (7) Booster Pump (8) Check Valve

Previous

Next

Get a quote

Related Products

Nationwide sales hotline available 24/7

Address: Building 12, No. 168 Kechang Street, Qiubin Subdistrict, Wucheng District, Jinhua City, Zhejiang Province

E-mail:

Tel:

在线客服添加返回顶部

右侧在线客服样式 1,2,3 1

图片alt标题设置: Guangyuan Environmental

表单验证提示文本: Content cannot be empty!

循环体没有内容时: Sorry,no matching items were found.

CSS / JS 文件放置地